Sheet Metal Forming

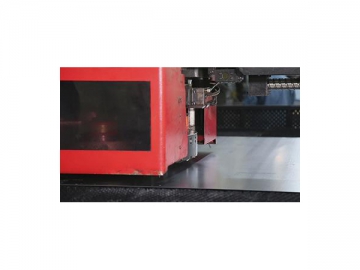

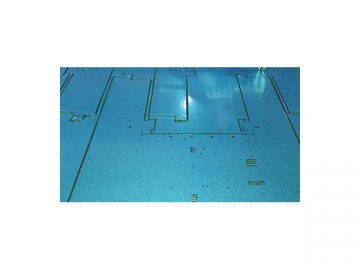

In the beginning of sheet metal fabrication, Jiatong will stamp the entire sheet metal after lasercut.

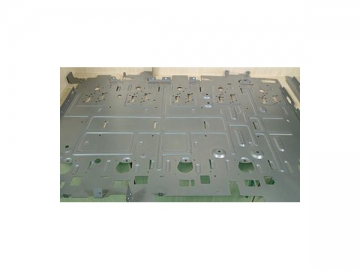

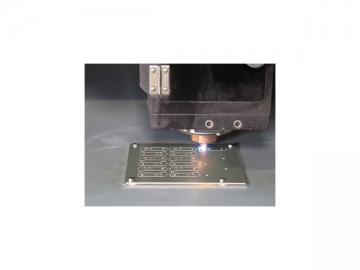

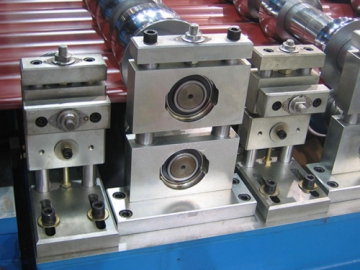

The Jiatong fabrication facility is equipped with an Amada CNC punching press to punch shapes out of sheet metal workpieces. Applying our extensive experience, we were able to find the best CNC punching presses for our operations in terms of performance and stability. Therefore, we use AE-2510NT/ and EM-2510NT/ models because they offer high-speed performance, punching 5 times per second. These machines can ensure the precision of the hole and hole position with a margin of error of ±0.03mm and ±0.1mm, respectively.

When utilizing our CNC punching press, Jiatong assembles the square and round molds to replace the punching molds, which minimizes cost and greatly shortens the delivery time. With these CNC punching presses, our processing capabilities is greatly enhanced. Jiatong can process orders of any size and will deliver the order within a few days.

For the special requirements present in customer drawings, such as embossing and rib reinforcements, the normal processing needs custom punching molds which can be expensive and time intensive. Our methods save time and money by using simple molds first and then we cut a template with a laser cutter and finally form the workpiece with a hydraulic machine. The entire process is fast, efficient, and affordable.

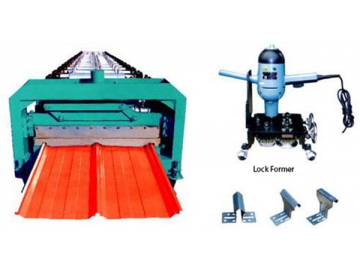

Sheet metal press brake service, also called bending service, is an indispensable procedure in sheet metal processing. According to the different products types, considering the bending radius and bending radian, we adopt high strength bending machines to bend the material.

Jiatong combines large-scale and small-scale bending machines. These bending machines are from TOYOKOKI and Amada. The key to processing high quality products is the processing equipment. The length of the products we can bend is up to 3m and thickness of the product can be within 0.1-6mm. Therefore, it is possible for us to process all of the products you need.