Self Inspection

Our physical and chemical center is equipped with a full range of professional testing equipment, which includes 60 ton universal tensile testing machine, low temperature (minus 196 degrees) impact testing machine and metallographic microscope, enabling us to ensure the quality and functionality of both raw material and finished product.

- Tensile testing machine

Tensile test data record

Tensile test data record  Metallurgical microscope laboratory

Metallurgical microscope laboratory  Low temperature impact tester

Low temperature impact tester

We will conduct non-destructive examination on the surface and the weld joint through different types of testing, such as Radigraphic Test (RT), Ultrasonic Test (UT), Penetrant Test (PT) and Magnetic Particle Test (MT). In this way, we can ensure the final product free of cracks, defects and with uniform wall thickness.

Ultrasonic testing

Ultrasonic testing  Magnetic particle inspection

Magnetic particle inspection  Wall thickness detection

Wall thickness detection  Ferrite detection

Ferrite detection  Colorant penetrant inspection

Colorant penetrant inspection  RT ray detection

RT ray detection

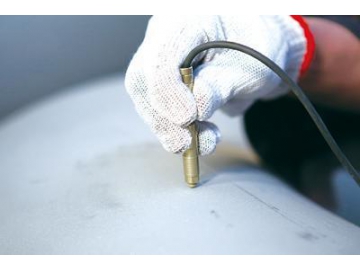

In addition, we will utilize vernier caliper and ultrasonic thickness gauge to accurately measure the wall thickness, outer diameter and inner diameter of our finished pipe fittings. Then hardness tester will be used to test the hardness. Through Positive Material Identification (PMI) via optical emission spectrometer, we can analyze the chemical elements in our finished product. As a result, both physical and chemical properties of our product are ensured to meet customers’ requirements.

Wall thickness measurement

Wall thickness measurement  Ultrasonic thickness gauge

Ultrasonic thickness gauge  Outer diameter detecting

Outer diameter detecting  Vernier caliper

Vernier caliper  Direct Reading Spectrometer

Direct Reading Spectrometer  Hardness tester

Hardness tester