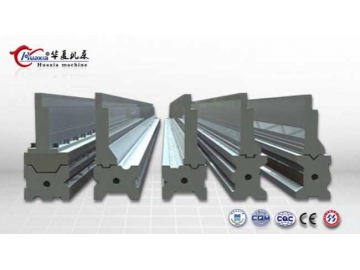

Robotic Sheet Metal Press Brake

Robotic Bending Solutions:

ACCURL press brakes can be used in a robotic cell, and either completely robotic, or simultaneously with a robot and a human operator alternating usage of the CNC machines.

Thanks to the ACCURL bending robot and automatic loading/unloading devices, the cell with two levels of automation - process and operation - is a reliable solution for unattended production, even at night.

All risks associated with part handling during bending are faced by the robot and not by the operator.

| Model | JPR16 | JBR30 | JBR110 |

| Instructions | Fast, high dynamics | Flexible, suited for small-sized part handling | Versatile, suited for medium-sized part handling |

| Payload | 16 Kgs | 30 Kgs | 110 Kgs |

| Max. range of action | 1610mm | 2230mm | 3100mm |

Connections:

The ACCURL Robotic bending cell system can be equipped with different types of loading and unloading connections, depending on the client's production requirements.

•Loader from a pre-centred pack.

•Loader from a Cartesian feeder in masked time.

•Cartesian feeder with controlled axes.

•Feeder/unloader for connection in line with ACCURL systems.

•Unloader.

•Carousel unloader.

•Roller-surface unloader for pallets.

•Roller-surface unloader for pallets and crates.

•Un-intrusive machine integration with sensors to back gauge fingers and bending beam which follow the programmed sequence of the Accurl press brake.

- Bending robotic cell for press brake

AUTO CONFIGURATION:

Loading with Cartesian robot and highly autonomous multi-purpose unloader.