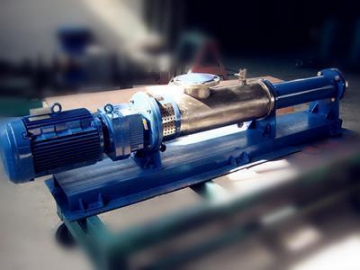

Progressive Cavity Pump in Pulp Slurry Pumping

Metering progressive cavity pumps are utilized by operators in the industrial applications for the transportation of different kinds of pulp slurries. The pumps are used to transport glidants, brighteners, dispersants, cooked starches, adhesives, and PVAs. S class progressive cavity pumps are used in pulp slurry applications to move pulps, papermaking sewage, dewatered sludge, and much more.

Pump type:

Recommended medium: Pulp slurry

Flow: 0.6M3/H

Pressure: 2Bar

Motor power: 0.55KW

Pump type:

Recommended medium: Dewatered sludge

Flow: 3M3/H

Pressure: 30Bar

Motor power: 22KW

Pump type:

Recommended medium: Paper dyestuff

Flow: 3M3/H

Pressure: 4Bar

Motor power: 3KW

Pump type:

Recommended medium: Pulp slurry

Flow: 50M3/H

Pressure: 2Bar

Motor power: 11KW

Pump type:

Recommended medium: Wet strength agent

Flow: 0.27M3/H

Pressure: 12Bar

Motor power: 0.75KW

Pump type:

Recommended medium: Fractionation agent

Flow: 7M3/H

Pressure: 10Bar

Motor power: 5.5KW

Pump type:

Recommended medium: Dispersant agent

Flow: 38M3/H

Pressure: 3Bar

Motor power: 7.5KW

Pump type:

Recommended medium: Calcium carbonate

Flow: 2M3/H

Pressure: 4Bar

Motor power: 1.5KW

Pump type:

Recommended medium: Starch

Flow: 1.6M3/H

Pressure: 4Bar

Motor power: 1.5KW

Pump type:

Recommended medium: Starch

Flow: 1.6M3/H

Pressure: 4Bar

Motor power: 1.5KW