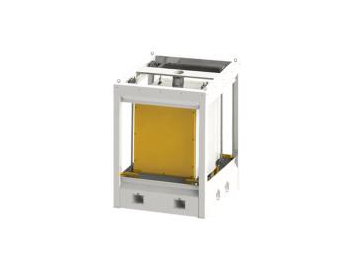

Square Plansifter

As one of the most essential machines in flour production line, the FSFG series square plansifter is primarily applied to sift and grade the ground materials, and it can work as an inspection sifter. Aside from food processing industry, it also fits for the manufacturing of wine, medicine, plastics, chemicals and other powder-related products. This device is widely accepted on the market as a result of its remarkable characteristics as demonstrated below.

1. Patented Aluminum Alloy Sieve Frame

a. The aluminum alloy sections are meticulously and precisely machined and then assembled to form the sieve frame. For sieve frames that share the same specification, they can be interchanged with each other freely, and this is also realized for inner frames. The inner frame can be rotated by 90 or 180 degrees when working with sieve frame, and its diagonal length error is not over 0.3mm. In addition, the height and length for the sieve frame and inner frame deviate little from standard values.

b. The aluminum alloy possesses pretty high rigidity and strength. So, the sieve frame is firm enough to avoid deformation, and its service life is prolonged.

c. As revealed by the destructive test, the aluminum alloy sieve frame is 4 times stronger than one made of wood. This makes our square plansifter more durable.

d. The aluminum alloy shows good resistance to water and damp, and it won't change its shape under the effect of aging. There is a layer of aluminum oxide on the surface, and it is highly resistant to wear. This compact layer is long-lasting, so, undesired material mixing won't take place.

e. The chemical compositions of the sieve frame meet the sanitary requirement in China. Only a little tailing is generated from aluminum machining stage to the final assembly, and the tailing can be recycled through simple smelting. Moreover, even if the screen frame is completely scraped after many years of service, it can be reused after smelting. On the other hand, the implementation of aluminum alloy sieve frame also cuts down the requirement for wood, thus well protecting the forest and improving the ecological environment.

2. Excellent Sanitation

a. For this square plansifter, all the interior surfaces of stock bin that may come into contact with materials are effectively isolated to improve sanitary condition.

b. The product-carrying channels are equipped with partition boards to separate and control the material stream, thus avoiding the generation of dust.

c. The product-carrying channels are easily accessible and can therefore be cleaned with minimum effort.

d. The sieve frames are easy to install and remove, while the sieve stack can be easily and securely clamped with the patented clamping device.

3. High Sifting Capacity

Our square plansifter makes fully use of the space, and it has larger sifting area. So, it shows high sifting capacity in a given space. The specific high-intensity concentric rotation guarantees optimized throughput.

4. Easy Cleaning and Maintenance

As mentioned above, the sieve frame is manufactured from high-quality aluminum alloy, and the screen mesh sticks to the aluminum alloy inner frame by glue. The sieve cleaner and arms guarantee that both the mesh and the sieve tray are effectively cleaned, and the cleaner allows direct access without the help of any tools. Furthermore, the mesh just requires the minimum maintenance.

5. Flexible and Reliable Application

According to various applications, this square plansifter can adopt different sieve combinations, such as common sieve frame, enlarged sieve frame, etc.

| Model | Number of compartments | Number of sieves per compartment | Sieve area (m2) | Main shaft speed (r/min) | Rotation diameter (mm) | Sieve frame size (mm) | Drive motor (kW) | Overall dimensions (L×W×H, mm) | Compartment height (mm) | Sieve frame height (mm) | Weight (kg) |

| | 4 6 6 6 6 8 | 22~27 22~27 24~30 22~27 24~30 24~30 | 23.04~27.94 34.56~41.90 38.88~47.31 48.96~57.60 55.08~65.45 73.44~87.26 | ~245 | ~64 | 640 640 640 740 740 740 | Y132S-6-3 Y132M1-6-4 Y132M1-6-4 Y132M2-6-5.5 Y160M-6-7.5 Y160L-6-11 | 1780×2410×2430 2550×2410×2430 2564×2360×2580 2830×2814×2430 2885×2566×2580 3760×2766×2580 | 2150 2150 2300 2150 2300 2300 | 1835 1835 1985 1835 1985 1985 | 2700 4200 4100 4700 4950 6200 |

Related Names

Flour Sieving Equipment | Wheat Flour Sifter | Flour Classifying Machine