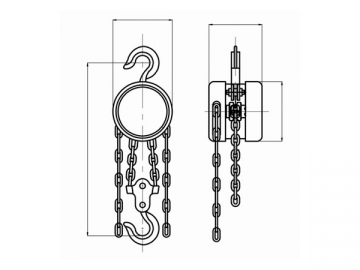

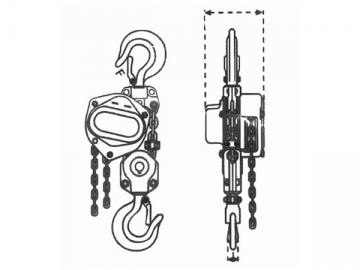

308 Non Sparking Manual Chain Hoist

Our 308 non sparking manual chain hoist helps in many ways. In a combustible or explosive atmosphere, the tool is either used to lift heavy loads or assist in repair and installation of machine parts.

Work Principle

Operators pull the chain on the side of chain hoist. This turns the small drive gear and makes it rotate. Subsequently, the large driven gear that meshes with the drive gear starts to turn. This gear mechanism enables an amplified torque output which creates the motion for lifting and lowering goods. On the inner side of the chain is fitted with pawls. The pawl and gear forms an assembly that resembles a ratcheting mechanism which allows the wheel to rotate in only one direction.

The manual chain hoist is assembled, commissioned, and tested in strict accordance with the related State standards for lifting equipment. Its explosion proof performance meets the GB/10686-89 standard.

Important

1. Before operating the manual chain hoist, make sure all its parts and components including every chain link are in good condition. Apply lubricating grease to the shafts as well as gear teeth to reduce wear, thereby improving the use life of equipment.

2. There should be no dislocated links on the lifting chain, as the chain would be used to lift or lower heavy goods in only the vertical direction. This ensures the hoist can start smoothly. Do not use the hoist to lift goods that exceed its rated capacity.

3. Operators should pull the chain in directions that are in the same plane as the chain wheel stays. Any pull in directions other than the above would potentially cause the chain link to be stuck between gear teeth.

4. Use even force to pull the chain, in order to avoid jumping chain or stuck chain. If any difficulty is founding in pulling the chain, please inspect the chain and identify the problem. Do not force the stuck chain to move by applying greater amount of force to the chain in case it would snap.

5. If necessary, you can hang our manual chain hoist to a tripod. The three feet of the tripod should be kept at a distance from one another. Ropes should be used to connect between two feet. When the tripod needs to be put on the ground, care is taken to prevent site workers from tripping over it.

6. The lifting height should no exceed the rated height. This would prevent the chain from snapping which might lead to accidents.

7. While the hoist is lifting goods, workers should not be allowed to work or walk beneath the hoist in case the goods would fall accidentally to cause injuries to workers.

8. The first focus of selecting the right manual chain hoist should be its explosion proof performance, followed by its mechanical performance. A hoist can be thought of qualified only when the said two factors meet the related standards. It would be expected to have been subjected to drop forging process to attain high tensile strength, long service life and stable mechanical performance.

1. JB/T 7334 standard compliant

2. National patent: ZL200310109687.4

3. Size: FBHS

| Model | Capacity T | Lifting m | Weight kg |

| 308-1002 | 0.5 | 2.5 | 10.2 |

| 308-1004 | 1 | 2.5 | 13.6 |

| 308-1006 | 2 | 2.5 | 22 |

| 308-1008 | 3 | 3 | 23.6 |

| 308-1010 | 5 | 3 | 36 |

| 308-1012 | 10 | 3 | 68.5 |

| 308-1014 | 16 | 3 | 187 |

In addition to the above models, we also provide tailor-made products based on customer-specific requirements or the technical drawings customers provide us.

Related Names

Manually Operated Hoist Manufacturer | Lifting Device in Underground Mining | Load Lifting Method