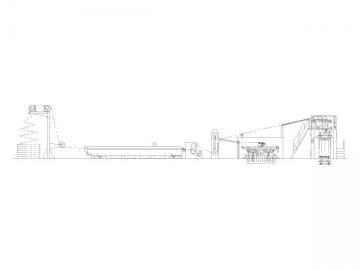

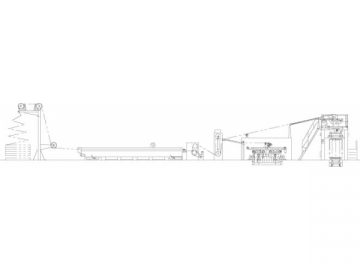

LHDL Rod Breakdown Machine for Aluminum or Aluminum Alloy Wires (Sliding Type)

Application

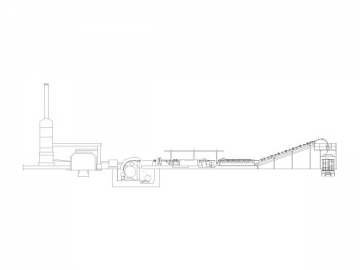

This sliding type aluminum rod breakdown machine draws the Φ9.5mm aluminum or aluminum alloy rod into Φ2.1 ~ Φ4.5mm aluminum alloy or Φ1.8mm ~ Φ4.5mm aluminum wire. The aluminum rod after drawing will be coiled by a dual spooler.

Features

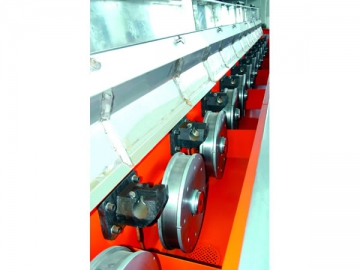

1. Drawing capstans applied by the sliding type aluminum rod breakdown machine come with the diameter ofΦ450mm. They are arranged in a line.

2. Different motors are separately used to drive constant-speed wheels and wire-drawing wheels. Speed of those wheels is synchronously adjusted, so that the quick change of die can be realized.

3. The wire drawing bench applies the programmable controller and touch screen, both of which are good for coordinating the working status of all the parts. With the touch screen, you can set and modify the parameters. This controlling system is characterized by advanced level, reliability, and convenient operation.

Improvement

This cable making machinery adopts a new type coiling system which not only speed up the working efficient but also decrease the failure rate.

Advantages

1. The sliding type aluminum rod breakdown machine utilizes the gear processed by grinding. For that reason, it makes little noise.

2. A one-piece casting transmission box offers an effective solution to the oil leakage problem.

Sales Performances

The first rod breakdown equipment was sold to Jiangsu Province in 1999. Our machines have been exported to India,Russia, Africa, Burma, Turkey,Thailand, Egypt, South Algeria, Indonesia, etc.

| Drawing capstan dia. (mm) | Drawing times | Applicable wire dia. (mm) | Dia. of finished product (mm) | Max. drawing speed (m/s) |

| 450 | 9 | 9.5 | 2.8-5.0 | 16 |

| 450 | 11 | 9.5 | 2.2-5.0 | 22 |

| 450 | 13 | 9.5 | 1.8-5.0 | 25 |