Eco-friendly Optical Mirror

This product has been discontinued and removed from our shelves.

The lead free mirror is our in-house produced product. It is ultra-thin and free of heavy metals. The raw material for mirror production is superior-quality float glass, which comes from Germany, Japan, Belgium, Italy and China. This product has been specially treated for environmental protection. It has been certified by the third-party authority. The lead-free mirror can be produced in two different types. The conventional type has a thickness range from 1mm to 5mm, and its back paint is grey or white. The special type has a thickness range from 0.5mm to 0.7mm, and its back paint can be customized upon request. Our company holds a diverse range of mirror plate production facilities, including 7 vacuum coating machines, 4 spray painting lines, cleaning equipment, mirror polishing equipment and so forth. The yearly production capacity reaches 5 million square meters.

What is the difference between the eco-friendly optical mirror and the rearview mirror of the environment friendly car?

The rearview mirrors are curved glass optical mirrors, while eco-friendly optical mirrors are made from plane glass optical mirrors.

Material properties

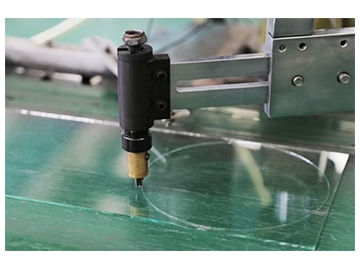

The 0.5mm to 5mm eco-friendly optical mirror is made from glass coated with an aluminum based film applied using a vacuum sputtering process.

Application

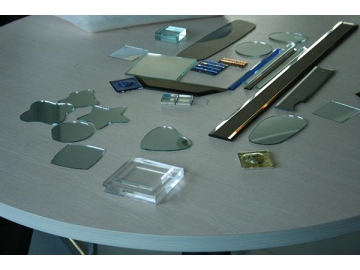

The eco-friendly optical mirror is mainly used for cosmetic packaging (including but not limited to: makeup mirrors, BB cream packages, powder boxes, cosmetology mirrors, etc.), intelligent bathroom mirrors, emitter optical lenses, etc.

Process characteristics

The production process is advanced and can be strictly controlled. It is also environmentally friendly and the finished product’s reflectivity can be between 10%-80%, meaning it can be used in weak light environments.

Product specification

Dimensions: 1245×1092mm, 1220×914mm, and smaller dimension in any shapes. The product can be customized by altering dimensions.

Test method

1. Visual inspection: when the tested mirror is placed under the 30 watts daylight lamp, the naked eye cannot find detect abnormalities from a distance of 40cm, including but not limited to spot defects, scratches, bubbles, discoloration of the film and edge damage, etc.

2. Chemical test: the lens to be tested is laid in the 5% concentration NaCl analytical reagent solution at a temperature of 40 degrees. After 172 hours, if the lens’ film is not showing signs of turning black or discoloring in other ways, it is qualified.

3. Apply the cross cut adhesion tester to perform cross-cut testing for the black paint, and if the black paint is not flaking, but is well protected, then the production is qualified.

4. Function test: using a UV2000 spectrophotometer and spectral analyzer to detect whether the hue of reflectivity film meets the requirements of the specification or the color and reflectivity the customer required.