GENZON Cold-Chain-Ammonia Automated Cold Room

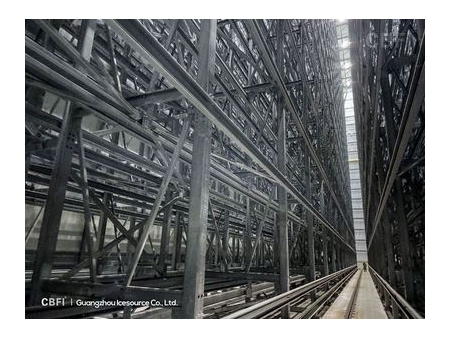

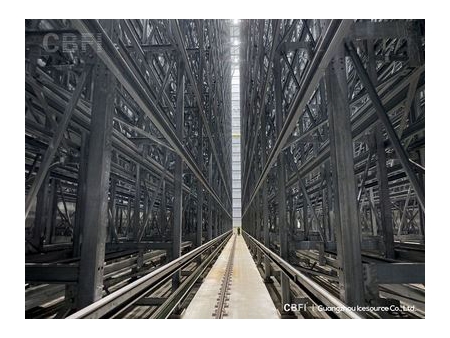

Introduction: GENZON clod chain automated cold room is a transit center of the cold chain logistics, a comprehensive distribution base integrating the electronic storage information and trading platform. This cold room is a rack supported warehouse and covers an area of 22,000 m2, with a height of 45m (including 9 m below the ground) and a temperature controlled space of 400,000 m3. The temperature range is -25℃~-18℃ and its capacity is 100,000 tons. This cold room can provide professional and efficient storage service for food, medicine and other industries.

Automated cold room adopts automatic control and mechanical equipment for automatic storage and retrieval. Actually, the freezing and refrigeration refers to the temperature, the cold room is a constant temperature storage under a low temperature condition.

- According to the calculation, RWKII65-CM is selected as the host, including 5 cold storage units. When the economizer is running at full load, the enclosed loading dock can be used. But an enclosed loading dock runs longer and is always used during daytime. Domestic cold storage works at night during the period of off-peak power, and then the enclosed loading dock cannot cover the need. Thus, another high temperature refrigeration equipment RWKII40-CM is selected for the enclosed loading dock and anteroom, which reduces the operation cost.

- The air cooler supplies liquid refrigerant by gravity, eliminating the investment and operating cost of the ammonia pump. Based on the operation of 18 h per day, the electricity consumption can be saved by 1%. This also allows for easy automatic control. Considering the layout of the cold room, buffer room, enclosed loading dock and anteroom, and the use of centralized forced ammonia pump for liquid supply, the air cooler should be placed in basement floor or the ground floor.

- The refrigeration system adopts the secondary throttling liquid feed, saving energy by 3-5% compared with the conventional systems.

- Unique defrosting technology: After defrosting, all the hot ammonia flows back to the centralized flash economizer, which is beneficial to the smooth drainage and improves the defrosting effect.