Furring Channel Ceiling System(Standard Type)

Furring channel ceiling systems are mainly composed of main carriers and furring channels. They are lightweight, easy to install and can be free cut and combined without using professional cutting tools so that you can complete installation in very short time. They are widely used for the ceiling decoration of houses, hotels, office buildings and malls to provide reliable fireproof performance and long service life. Besides, furring channel ceiling systems used metal frames are in simple shapes and easy to process, so their output is larger than that of profiled channels. As a professional light-gauge steel framing products provider, we can realize daily output of more than 100 tons and we also have large quantities of inventories, which can ensure in-time delivery.

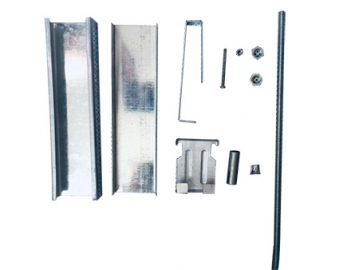

We can independently manufacture and provide all metal channels and connection accessories in furring ceiling systems. Just by matching with bearing gypsum boards or fiber cement boards, a complete furring ceiling system can be formed.We provide the following products for furring ceiling systems:

- Suspender

- Hanger (Used for the connection between suspender and main carrier)

- Preformed wire clip (Used for the connection between main carriers and between furring channels)

- Channel bracket (Used for the connection between main carrier and furring channel)

- Brackets (Used for the seam connection between sheet metals)

- Expansion screw, nut

- Fix hangers on suspenders with screws

- Pass main carriers through hangers and fix with screws

- Fasten and connect furring channels with main channels using channel brackets

- Main carrier interval 1000-1200mm, furring channel interval 300-400mm, suspender interval 1000mm. Arrange and combine in turn, then metal stud ceiling framing will be completed

- Fix gypsum boards on furring channels by using self drilling screws

- Connect sheet seams by using cross-bracing channels

- Install expansion screws on suspenders, and fix with walls or rubber boards

- Install edge channels on edging parts or carry out edge-wrapping treatment with cement or gypsum, which can effectively reduce edge cracking