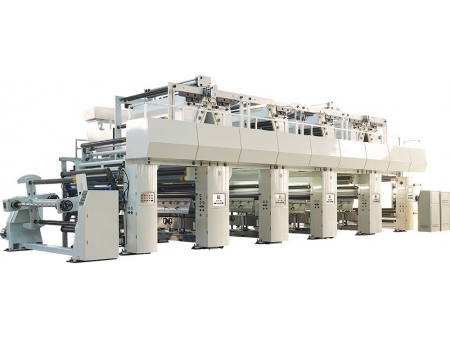

Doctor Blade for Gravure Printing

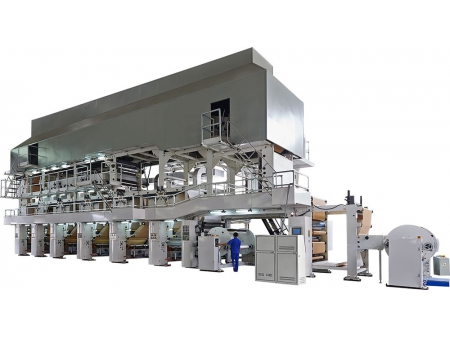

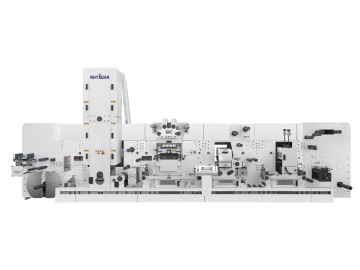

Gravure printing is a direct printing method in which ink is transferred in cells to the substrate. The advantages of gravure printing are a wide application range, high print quality, and large scale printing and anti-counterfeit performance. Compared with other printing methods, rotogravure printing has high printing speed, large sheet width capability and minimal downtime, so doctor blades for gravure printing must be able to adapt to high speed and extended printing times. The blades need to have a long lifespan in order to reduce the change time of doctor blade and increase efficiency. Considering the above requirements, we recommend the following doctor blades which have high precision, good durability, long lifespan and are suitable for gravure printing.

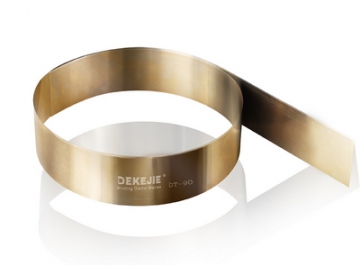

- Maximum speed is 500m/min。

- Low pressure between blade and cylinder improve the lifespan of blade

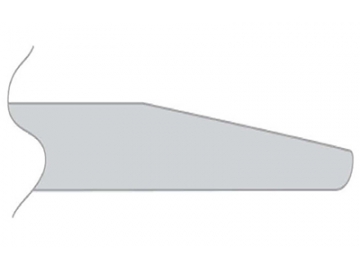

- Maximum speed is 400m/min。

- Good durability and corrosion resistance of doctor blade can reduce the wear of air cylinder resulting from blade.

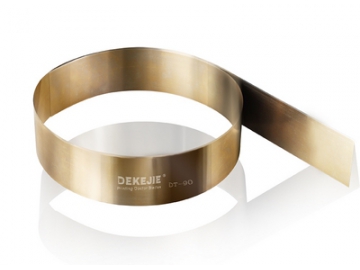

- Maximum speed is 400m/min。

- Good durability of doctor blade can reduce the wear of cylinder resulting from blade.

- High quality coating makes the doctor blade have good corrosion resistance.

- Maximum speed is 250m/min。

- The good effect of removing excess ink reduces excess ink.

- Due to the polishing process, there is no need to grind blades before using.

- Maximum speed is 250m/min。

- There is no need to grind blades before use.

- Appropriate price makes frequent change of blade possible.