Cutting Bed Department

The cutting bed department is used for material stripping, rough shape cutting, general cutting, paper pattern and sample plate checking, confirmation for first samples, and sampling inspection. The inspection processes ensure off-cut levelness and the correctness of front and back facing, direction and pattern of the cuts, and the exclusiveness of flaws such as deformation, aberration, drawn yarn, and stains. The department is equipped with four column oil double cylinder press cutting machines, radial oil press cutting machines, large/small leather skiving machines, slitters, sanders, and vacuum pumps.

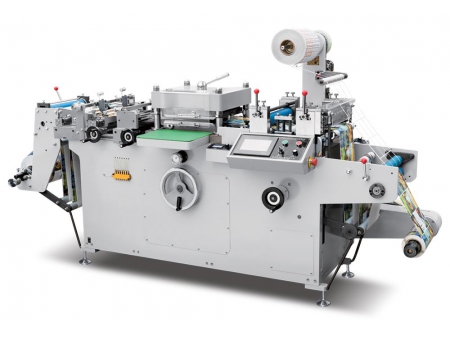

The four-column oil double-cylinder press-cutting machine is mainly used to cut non-metallic materials such as foamed materials, textile packing materials, leather, plastics, fabrics, cardboard materials, etc.

(The four-column oil double-cylinder press-cutting machine features several advantages. Firstly, the machine operates intermittently and can only be started by pressing the buttons with two hands simultaneously, which, combined with the emergency stop device, ensures safe operation. Secondly, both the precision and durability are respectively kept constant and are optimized by the self-lubricating system. Thirdly, precise and neat cutting of the off-cuts is achieved by automatic laser cutting.)

The slitter is mainly for the cutting of such materials as umbrellas, foam, leather, reflecting materials, nylon, chiffon, denim, screen cloth, rubber, oxford fabric, non-woven fabrics, double-faced adhesive tape, acetate etc.

(The slitter features several advantages. Firstly, the high-efficiency and cleanness of the machine is ensured by its clearance sharpening system, diamond grinding wheel and dust exhaust apparatus. Secondly, the machine can be set to cut the material into specific width and number, thus the width and number of a bunch of binding tape can be accurately determined. Thirdly, the cutting data of each batch of cloth is automatically recorded. Fourthly, the parallel cutting precision of the machine is high up to 0.1mm with the adoption of imported ball screw and sliding rail, which makes it less prone to wear. Finally, the operational safety of the machine is guaranteed by the triangular spatial support and the emergency stop button.)

The radial oil press-cutting machine is used to cut synthetic materials, such as leather, rubber, canvas, nylon, cardboard etc.

(The radial oil press-cutting machine features several advantages. Firstly, it delivers high-efficiency operation, low failure rate, and is less noisy. Secondly, the lower stroke limit of the machine can be controlled by digital delay circuit and the working range of the swing arm can be adjusted using the hand wheel. Thirdly, the safe operation of the machine can be guaranteed by regular manual inspection and automatic oiling for the column.)

The large leather-skiving machine is used to layer leather meant for wallets, cloth, luggage cases, furniture, car interiors, and gift wrap.

The sander is employed to polish edge-painted accessories of handbags/leather-ware, which makes smooth and level the surface of the off-cuts made of PU/genuine leather.

The small leather-skiving machine is used to layer materials such as leather, PU leather and rubber.

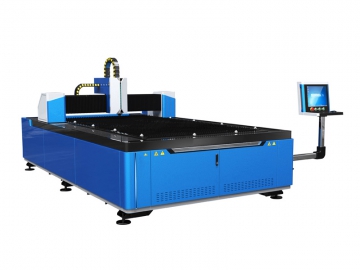

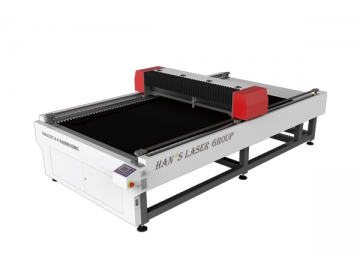

The laser cutter is applied to conduct laser cutting and engraving of non-metallic materials