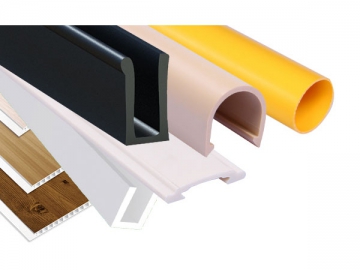

Custom Plastic Extrusions

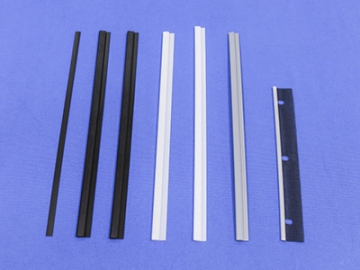

Plastic extrusions are similar to metal extrusion products as they are formed by forcing molten plastic through a specially designed die. Using the plastic extrusion process, you can produce custom long plastic profiles, plastic tubes, plastic channels, plastic strips, plastic trims, plastic seals and any other plastic shapes. We have the capabilities to manufacture virtually any plastic grade materials, including PVC, rigid PVC, ABS, PE, polystyrene, polypropylene, polycarbonate and many other thermoplastic extrusion materials.

Shangyu owns years of experience in custom plastic extrusion manufacturing, and we have fully mastered every single technique in plastic extruding. Shangyu is an experienced and productive manufacturer with monthly output of 300 tons of plastic extrusions.

You are only asked to provide us your samples, drawings or even just a brief idea, and we promise to offer you custom plastic extrusion parts perfectly meet your specifications with the highest quality standards.

PVC, or polyvinyl chloride, is a healthy, environmental friendly and safe material for a wide range of plastic products since its non-toxic, nonmagnetic, no heavy metal, no radiation, non-harmful gas emissions and etc.

PVC is highly cost effective due to its cheap price and simplicity of manufacturing.

PVC extrusions have advantages of light weight, flame retardant, moisture resistant, noise insulation, thermal insulation, impact resistance, UV protection and etc.

PCV products require minimum maintenance because they will never rot or rust.

- 01.Samples or Drawings

As long as you provide us your drawings or samples, and tell us your specific requirements, our engineers and designers will evaluate the project based on provided conditions. We will see if we can optimize your product design according to your specific usage and using places and offer certain recommendations. Final production plan is not made until the final design is confirmed by us both sides.

- 02.Mold Design and Mold Manufacturing

Since all PVC profiles are made from extruding machine, so we need different molds for different shaped PVC profiles. We have professional mold designer who can design and manufacture molds perfectly match the extruded plastic application.

- 03.Raw Materials

The most commonly used material is PVC powder and it significantly saves the production cost compared to use traditional PVC granules, but if you have specific requirements on raw material, you can always contact us regarding to custom manufacturing.

- 04.Manufacturing

We use twin-screw extruder to reach higher production efficiency and higher product quality. According to specific plastic profile requirements, we also apply the best fit technique to reach higher quality such as threads, calibrators, cooling baths, cutting system or other auxiliary equipment.

- 05.Testing and Conformation

We will send our sample to customers for confirmation, and if they request to test on the product performance, we have our own testing laboratory resources and test on plastic profile fire proof property, noise insulation, thermal insulation, impact resistance, color fastness, hardness, contaminants and etc., and provide our customers with detailed test report.

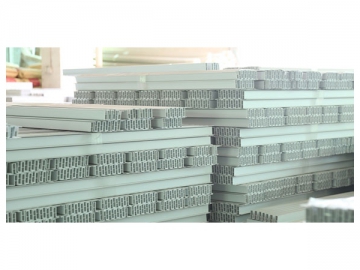

- 06.Mass Production

Once our samples have been confirmed by our customers, we can start for mass production. Shangyu is equipped with three twin-screw extruding lines and satisfies monthly output of 300 tons of plastic extrusions. We promise you with the fastest possible manufacturing speed and delivering speed.

- 07.Pack and Transportation

Shangyu provides different packing styles for your choice such as wooden boxes, cardboard boxes, winding profiles, heat-sealed bags, large-scaled trays, metal cages and etc. and deliver them to your hand with the best condition.