Wall Panel Types

Construction wall materials are generally divided into three types including bricks, blocks and panels. As a new wall material, light weight wall panel can replace the traditional structure of solid brick combined with concrete and is widely used as interior wall, exterior wall, roof panel, floor slab and bounding wall.

Light weight compound wall panels are prefabricated and produced in batch automatically in factories, so they are precise and stable. Moreover, they can be sawed, planed, drilled and nailed, so they can be directly assembled on site and then the construction is completed. The use of light weight wall panels as construction materials can reduce workers' labor intensity and shorten the construction period.

| Feature | Light weight wall panel | Brick wall | Aerated brick wall | Fiber cementwall panel |

| Solid | √ | √ | ||

| Moisture-proof | √ | √ | ||

| Sound-proof | √ | √ | ||

| Fire-proof | √ | √ | √ | √ |

| Simply installed | √ | √ | ||

| Structure saving | √ | |||

| Smooth surface | √ | √ | ||

| Low raw material price | √ | |||

| Easily transported | √ | √ |

- Calcium silicate board polystyrene compound wall panel

GRC lightweight wall panel

GRC lightweight wall panel

(Hollow core wall panel) Magnesite Partition Wall Panel

Magnesite Partition Wall Panel

( Silicon and magnesium aerated wall panels)

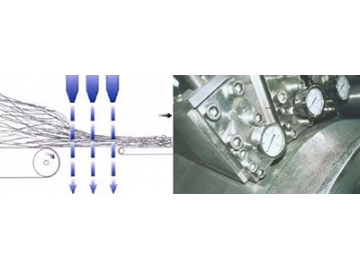

TYF-16A production plant is applicable for the production of two-side calcium silicate board lightweight compound wall panel or GRC lightweight wall panel and 10 pieces can be molded one time. Due to the mobility of equipment, the arrangement of production line is not easy to be limited and the line is highly automatic, which can save labor and increase production.

TYF-16B production plant is applicable for the production of two-side calcium silicate board lightweight compound wall panel or GRC lightweight wall panel and 10 pieces can be molded one time. It adopts stationary type design so that the operation is much easier and it can also reduce investment cost and lower the failure rate. However, it has certain requirements for the site.

TYF-01 production plant is applicable for the production of two-side calcium silicate board lightweight compound wall panel and 40 pieces can be molded one time. It adopts vertical design so that the occupation land area is smaller and the unit-price is lower. Therefore, it can save equipment investment cost and workshop construction cost for customers.

TYFZ16 production plant is applicable for the lot production of two-side calcium silicate board lightweight compound wall panel and over 40 pieces can be molded one time. It adopts hydraulic molding opening and closing method, which can avoid the hidden dangers of the manual one in traditional vertical machines.