CNC Mill-turn Machining Service

Material: SUS304

Product name: automation transmission parts

Material: SUS304

Product name: automation transmission parts

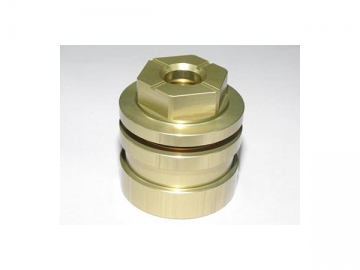

Material: AL6061

Product name: flow control components

Material: SUS304

Product name: precision transmission parts

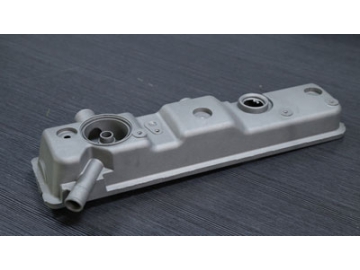

Material: AL6061

Product name: piston motion parts

The CNC milling and CNC turning lathe is used for parts that require a high precision and complex machining. Not only do we produce general gang tool turrets for 2 axis lathes, but we also have C and Y axis living tool turrets to achieve 3 or more axis control. This process carries out a variety of machining methods, such as milling, turning, drilling, and boring. Workpieces can be clamped in a single round and machined from multiple sides.

When conducting CNC milling and turning machining, the clamping tension can be effectively reduced in order to prevent human clamping errors, thus ensuring the form and position tolerance, as well as avoiding workpiece deformation and improving the precision of machined parts. The dual axis CNC Swiss style lathe carries out one-step machining of the raw material, as well as milling and turning of both the front and back of the workpiece. This also ensures the surface roughness of the workpiece.

Materials that can be machinedAluminum alloy: 2024, 5052, 6061, 6063, 6082, 7075.

Copper alloy: brass, bronze, BeCu, pure copper.

Special alloy: TA2, TC4, 4J29 (KOVAR), 4J36 (INVAR), high temperature alloy (INCONEL 718, 625).

Stainless steel: sus303, sus304, sus316, sus420, sus440c, sus630.

Engineering plastics: PP, PVC, PEEK, PI, POM, TEFLON.

| ITEM | Description | Qty | Model | Vendor | Size | Accuracy |

| 1 | CNC LATHE | 10 | STS-46 | SHENTESI | Slant (Φ250*350L) | 0.01mm |

| 2 | CNC LATHE | 10 | ST-52M | XINSHUO | 8 position turret+Y axis living tool (Φ190*370L) | 0.01mm |

| 3 | CNC LATHE | 4 | DL-20M | DALIAN LATHE | 12 position turret (Φ400*1000L) | 0.01mm |

| 4 | CNC SWISS-STYLE LATHE | 8 | ST-32MB | XINSHUO | (with back spindle) 5 axis swiss-style lathe (Φ300*300L) | 0.01mm |

- Our CNC milling and CNC turning machines are imported from Taiwan, Japan, America with other famous international CNC machine names to ensure the highest quality of precision parts and greatly reduced production error rates.

- We implement on-site inspection, testing and control of key data during the manufacturing process to timely monitor the dimensions and good quality of the workpieces.

- We use an ERP bar code system managing to ensure the data reliability and real time performance.

- We always study more techniques on improving production efficiency by shortening the production steps for workpieces that require batch production. It saves time and material costs.

- We always consider the satisfaction on customer requirements and that ensuring a highest quality of machining parts are always on their advantage.

- Asia America has more than 20 years of experiences in machining service and has exported production to Europe, America and Asian countries. We meet ISO9001 and TS16949 standards, ensuring the quality, low price and on-time delivery.

- We have provided services for international names, including AMETEK, FLIR, IMI Norgren, OHLINS, Spectris and other high-end customers.

- We have sales engineers with extensive technical background that would allow our cuztomers to communicate professionally and effectively.