CNC Machining Flow Control Components

Material: SS304

Product name: conduit of flow meter

Material: SS304

Product name: hot runner connector

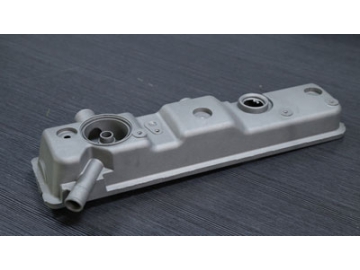

Material: aluminum alloy

Product name: flow control connector

Material: PEEK

Product name: petrochemical measure instrument

Material: aluminum alloy

Product name: food and beverage industrial precision flow nozzle

Material: brass

Product name: medical grade low temperature liquid valve assembly

Material: POM

Product name: instrument connector

What we can do?

Asia America machines cylinders, hydraulic cylinders, valves and other automation actuator parts. The flow control components we are capable of machining include hot runner connectors, hot oil pumps, socket connectors, shaft seals, electro-pneumatic actuators, electro-pneumatic regulator valves, bellows stop valves and more.

Materials that can be machinedAluminum alloy: AL6061, AL6063, AL6082, AL7075.

Copper alloy: brass, bronze, BeCu, pure copper.

Stainless steel: sus303, sus304, sus316, sus420, sus440c, sus630.

Engineering plastics: PP, PVC, PEEK, PI, POM, PTFE.

- Preform body

- Complete machine machining (turning + milling)

- Surface treatment

- Packaging and delivery

- Raw material preparation according to customer design drawing requirements.

- Cut the material with the sawing machine. The assembly workpiece adopts custom-built fixture.

- A CNC milling machine is used for rough cutting, and a CNC 4-axis (5 axis) milling machine or CNC turning lathe for machining of related sizes.

- Remove the burr and check the related precision hole, position and size and appearance.

- Conduct surface treatment according to the design drawing requirements. Then re-check the related precision hole, position and size and appearance.