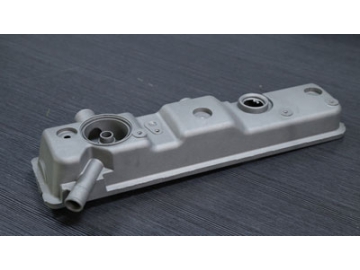

CNC Machining Encloser and Bracket

Material: aluminum alloy

Product name: optical instruments

Material: aluminum alloy

Product name: handle bracket of 3D Optical scanner

Material: aluminum alloy

Product name: variable focal length lens

Material: SS440C

Product name: polarized light camera lens holder

What we can do?

Asia America produces optical lens holders, encloser parts and other optical instruments. We also carry out machining of telescope parts, microscope parts, camera lens parts, optical scanner parts, infrared and ultraviolet ray transmitter parts, laser machine parts, sighting telescope parts, optical distance meter parts and more.

Materials that can be machinedAluminum alloy: AL6061, AL6063, AL6082, AL7075.

Copper alloy: brass, bronze, BeCu, pure copper.

Stainless steel: sus303, sus304, sus316, sus420, sus440c, sus630.

Engineering plastics: PP, PVC, PEEK, PI, POM, PTFE.

- Preform body

- Complete machine machining (turning + milling)

- Surface treatment

- Packaging and delivery

- Raw material preparation according to customer design drawing requirements.

- Cut the material with the sawing machine. The assembly workpiece adopts custom-built fixture.

- A CNC milling machine is used for rough cutting, and a CNC 4-axis (5 axis) milling machine or CNC turning lathe for machining of related sizes.

- Remove the burr and check the related precision hole, position and size and appearance.

- Conduct surface treatment according to the design drawing requirements. Then re-check the related precision hole, position and size and appearance.