Successful Spray Drying System for Ceramic Granules

Request a Quote

Description

The ceramic spray drying machine is applied in production of ceramic powder. It provides essential condition for production of fine ceramics and new material. This machine can be widely used in drying industry of materials such as zirconium oxide, aluminum oxide, zinc oxide etc.

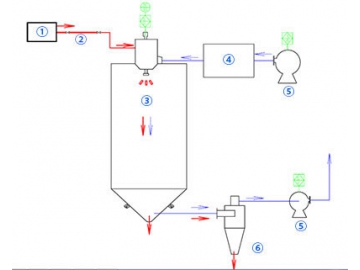

Process flow

- Conventional Spray Dryer

- Versatile Spray Dryer, Single Point Discharge

- Versatile Spray Dryer, Two Point Discharge

| Type | CSD-12 | CSD-16 | CSD-20 | CSD-25 | CSD-30 | CSD-35 |

| Application | Few quantity granulating in research and development | Few quantity granulating in research and development | Small scale production and granulating | Production granulating | Production granulating | Production granulating |

| Water evaporation (kg) | 5Kg/h | 10Kg/h | 15Kg/h | 30Kg/h | 75Kg/h | 110Kg/h |

| Drying room dimension (mm) | φ1200 | φ1600 | φ2000 | φ2500 | φ3000 | φ3500 |

| Ancillary facilities of drying room | Manhole, inspection window, illuminating window, product recycling tank, air hammer (3 at the conic section) | |||||

| Atomizing disc (ZrO2/SUS304) | MC-65 | MC-84 | MC-84/MC-100 | MC-125 | ||

| Speed r.p.m | 5000~15000 | |||||

| Product recovery | Low-Cap- Type, 2-point collection | |||||

| Material feeding method | Peristaltic pump | |||||

| Material pump volume | 10Kg/h | 20Kg/h | 30Kg/h | 60Kg/h | 150Kg/h | 220Kg/h |

| Heating source | Electrical heater | LPG combustion furnace | ||||

| Heater volume | 18Kw | 24Kw | 36Kw | 60Kw | 100000kcal/h | 150000kcal/h |

| Max hot air temperature | 300℃ | |||||

| Ancillary devices | Forced draught blower, exhaust fan, primary filter, hot air filter, cyclone separator, bag filter, operational ladder | |||||

| Instrument control | Hot air temperature display and adjustment alarm apparatus, exhaust air temperature display and adjustment alarm apparatus, atomizer frequency display, drying room pressure meter, hot air filter, differential pressure gauge, cyclone separator differential pressure gauge, bag filter differential pressure gauge | |||||

| Safety device | Over-temperature protection system for heater | Flameout check device | ||||

| Power | Power: 380V-3φ Instrument: 220V-1φ | |||||

| Electric power (installed capacity) | 21Kw | 27Kw | 40Kw | 70Kw | 8.5Kw | 10Kw |

| Outline dimension (m) | W2.4×L1.7 ×H1.9 | W2.7×L1.8 ×H2.4 | W3.2×L2.2 ×H2.5 | W3.7×L3.4 ×H4.9 | W5.3×L4.0 ×H5.9 | W6.2×L4.5 ×H8.0 |

| Installation weight | 950Kg | 1400Kg | 1600Kg | 2000Kg | 3400Kg | 4900Kg |

| Optional device | Temperature recorder, digital atomizer speed display, atomizer vibration tester, double-layer flap valve or flap valve, vibration screen | |||||

If you are enterprise processing ceramic products or raw material supplier for the ceramic processing company, this ceramic spray drying machine can satisfy your requirements. Besides this drying machine, Jiangsu Xiandao can also provide related supporting equipment sets which can compose drying production line according to your requirements. Thus it can provide complete solutions for ceramics processing.

Related products

Send Message

Most Recent

More

Other Products

Videos