Capability

As a professional custom hydraulic valve solution provider with over 10 years of experience and knowledgeable technical team, Gaoyu specializes in designing and manufacturing hydraulic valves with various functions, including directional valves, speed control valves, brake valves, etc. In addition, we also offer custom service to satisfy your special expectations.

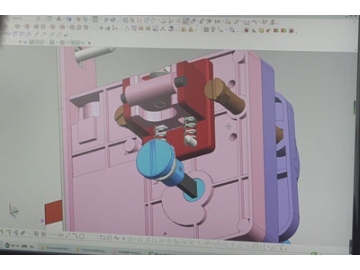

Digital production guarantees product quality and reduces costs. We are committed to improve our manufacturing capability with advanced software technology, including Pro/Engineer, AMEsim, PTC.MathCAD, SolidWorks, PCCAD V12, Product Data Management (PDM), data exchange platform and other test equipment like LERC for data collection and failure analysis.

Equipped with modern production facilities, we are able to achieve high productivity and efficiency at low cost. You can count on Gaoyu to provide you with the most reliable hydraulic valves for stable and precise operation.

- High Pressure Flushing Equipment

360° cleaning with no dead corner is achieved using 30 Mpa high pressure flushing and multi-axis coordination. Different flushing guns are optional according to different valve’s body, meeting different cleaning requirement. The high pressure flushing equipment is designed with PNC (programmable numerical control) system to reach high efficiency and to ensure consistent cleanliness level.

- Assembly Line

With high automation, the assembly line is well built according to product assembly sequence to ensure quick operation in each station, maximizing working efficiency and productivity.

CNC honing machine

CNC honing machine CNC center

CNC center Assembly line cleaner

Assembly line cleaner

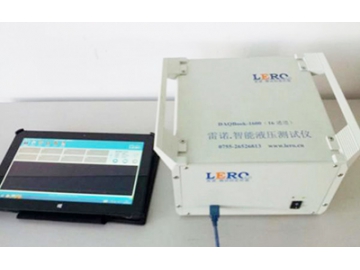

Quality control is the key to the reliability of the product. Our product quality is thoroughly and strictly controlled by advanced test equipment and highly qualified quality inspectors.

Lero hydraulic tester

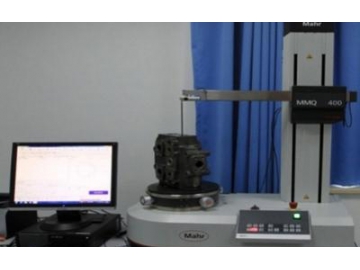

Lero hydraulic tester Mahr cylindricity measuring instrument

Mahr cylindricity measuring instrument Test bench for pilot valves

Test bench for pilot valves Performance test bench

Performance test bench Automatic carbon and sulfur analyzer

Automatic carbon and sulfur analyzer German BLUMTC50 test head and measuring bar

German BLUMTC50 test head and measuring bar