Automotive Rapid Prototyping

Rapid prototyping contributes to the concept and method stage before the direct manufacturing of products or molds of CAD model as well as the integration of processing works and the conceptual design of molds and products into a CAD or CAM diagram. In the automotive industry, rapid prototyping technique is used to create sample product which enables the manufacturer to conduct performance testing, verification of the design, evaluation and analysis. CAD graphics will be printed out into an actual object by the engineers during car exterior design and different materials are used to present the model in the design, therefore 3D printing technology is mostly used in car design and prototype creation as the model has to be created in a short period of time but with high accuracy.

Tenlita Model has long been cooperating with the automotive industry including manufacturers and Tier 1 suppliers regularly. For instance, Volkswagen, BMW and so on. We are well-known for prioritizing our customers and manufacturing high-quality prototypes.

Conceptual model, manufacture highly detailed models to expose the public to new concepts and thus the smoothness of the product surface is the crucial factor. This requires us to be innovative on the solution schemes as the design is typically not finalized.

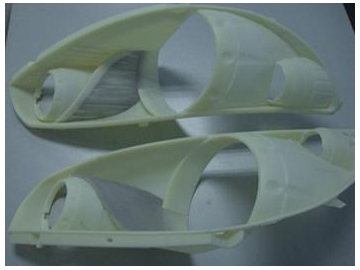

Component testing, large amount of various types of parts are involved usually. The requirements of the end product on its assembly parts indicate that the surface texture, color, mechanical property and so on are critical factors. Tenlita Model ensures all these based on extensive past experience and sophisticated equipment.

- Components processed by SLA, SLS or CNC techniques

- Lighting assembly parts of the car for concept and display purposes

- Interior decoration of the model

- Plastic parts, center console, car doors of the car