Automatic High Speed Corrugated Paperboard Production Line

Automatic High Speed Corrugated Paperboard Production Line

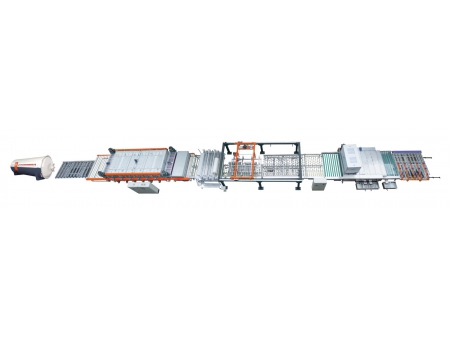

The automatic high speed corrugated paperboard production line is mainly composed of mill roll stand, single or double facer, preheater, glue coating machine, corrugated paperboard slitting and scoring machine, cross cutting machine, and stacker machine. This newly developed corrugated paperboard making machine is designed based on advanced international technologies, and also combines vast users’ feedbacks and our over thirty years of corrugated carton experience. It is characterized by high automation, high production efficiency, compact structure, as well as convenient operation and maintenance.

Carefully selected raw materials, such as steel plates, cast steel, cast iron, alloy steel, and low carbon steel, make sure all equipment composing the corrugated paperboard production line have high structural stability, and corrosion resistance. The manufacturing line with one year warranty is ideal for making three, four, and five layered corrugated paperboards with widths between

Related Names

Corrugated Fiberboard Making Machine | Corrugated Paperboard Manufacturing Line | Corrugated Board Production Line with Rigid Frame | High Speed Production Equipment