Deposited Lollipop Production Line

Deposited Lollipop Production Line

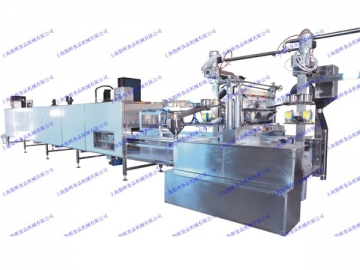

The fully automatic deposited lollipop production line is currently the most advanced lollipop pouring equipment in the domestic market. Integrating machinery, electricity and gas, it has a compact and reasonable structure as well as a high degree of automation. It has high working efficiency and can produce crystal dandies, bonbons, streaks sugar, xylitol, and sugarless lollipops with single color, two colors two flavors, two colors two flavors two layers, or three colors three flavors.

Our product is equipped with an automatic plunger system which has an accuracy rate of 99% or more. This equipment is produced according to the GMP standard, enabling food enterprises to easily pass professional certifications, such as GMP, HACCP, QS, etc. In addition, this equipment and the hard candy production line can be interchangeable.

Specification

Model | QH150B | QH300B | QH450B | QH600B |

Standard Production Capacity | 300kgh | |||

Max. Weight of the Lollipop | ||||

Diameter of the Lollipop | Flat 18 | |||

Size of the Bar | 60 | |||

Pouring Speed | 25-30 /min | |||

Steam | ||||

Compressed Air | ||||

Requirement of the Working Environment | Temperature 20 | Temperature 20 | Temperature 20 | Temperature 20 |

Total Power | 27KW/380V | 28KW/380V | 41KW/380V | 64KW/380V |

Length of the Entire Line | ||||

Total Weight | ||||

Lollipops produced by this equipment are shown below.