Fully Automatic Wafer Production Line

Fully Automatic Wafer Production Line

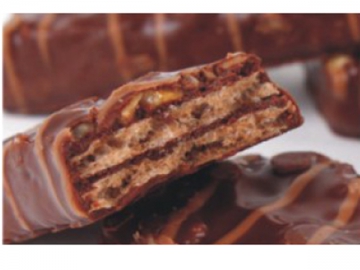

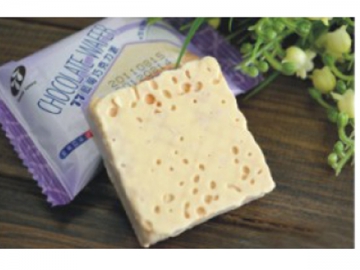

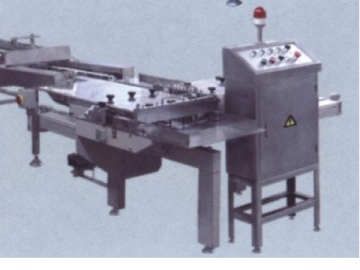

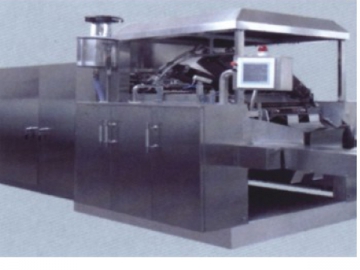

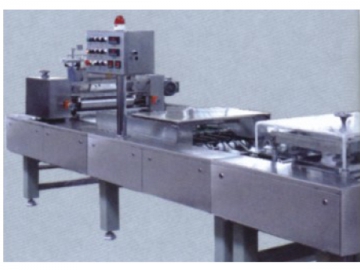

Combing advantageous of similar products from both home and abroad, the fully automatic wafer production line adopts electric heating as the heat source. It successfully solves the problems of high production cost and large color difference of the biscuit surface. It is composed of beating system, automatic feeding device, tunnel oven, transporting device, cooling device, coating machine, cutting machine, etc. With a compact structure and good stability, this equipment is the ideal choice for food manufacturers.

Specifications

Type | QH-27 | QH-39 | QH-45 | QH-51 | QH-63 | |

Yield(kg/24h) | 2500 | 3500 | 4000 | 5000 | 6000 | |

Gas Oven | Gas Consumption(kg/h)

Power(kw) | 18 | 25 | 25 | 32 | 40 |

2.2 | 2.2 | 3.3 | 3.5 | 3.5 | ||

Electric Oven | Installed Capacity(kw)

Power Consumption(kw) | 120 | 160 | 180 | 200 | 250 |

86 | 124 | 144 | 163 | 201 | ||

Size(mm) | 5930×1500×2500 | 8330×1500×2500 | 9470×1500×2500 | 10610×1500×2500 | 12890×1500×2500 | |

Our company provides five types of the fully automatic wafer production line, including QH-27, QH-39, QH-4, 5 QH-51 and QH-63. Our product features high thermal efficiency, good energy-saving effect, and long service life. The daily output is