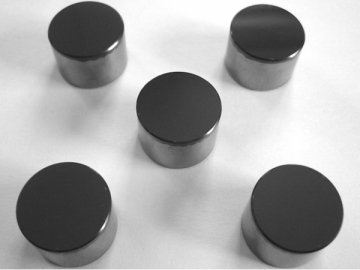

PDC Cutters

PDC Cutter

Features

1. ThePDC cutter has high abrasive resistance. High quality materials are sintered to form the diamondlayer which is of rigid framework structure. ThePDC features compact structure and good abrasive resistance.

2. The PDC cutter features good impact resistance. The PDC useshard alloy material whichhas good impact resistance and thediamond layer can guarantee thetoughness of the impact resistance.

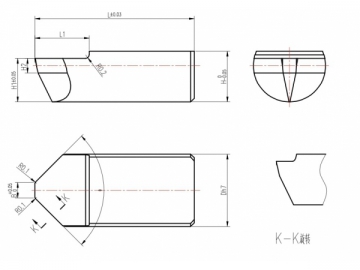

3. The PDC cutter has strongbinding force. The junction plane of thediamond layer and the hard alloy layer uses a corrugated tooth design. The binding force can be increased and thebad impact of the plane residual stress on the PDC performance can be avoided.

4. The PDC cutter has good self sharpening performance. The good organization microstructure of thediamond makes the diamond particle remain sharp all times.

5. The PDC cutter features good thermal conductivity. Its highest bearing temperature can reach

Application

The PDC cutter is used for drilling bits for oil, gas and coal.

Technical Specifications

| Typical Parameters of PDC Cutter | |||||

|

| |||||

| Available Size | Diameter(mm) | Overall Thickness (mm) | Thickness of PCD (mm) | Chamfer of PCD (mm) | Chamfer of Carbide (mm) |

| 0808 | 8.2±0.03 | 8.0±0.1 | 2.0±0.02 | 0.31±0.08×45。 | 0.31±0.08×45。 |

| 1308 | 13.4±0.03 | 8.0±0.1 | |||

| 1313 | 13.4±0.03 | 13.2±0.1 | |||

| 1608 | 15.9±0.05 | 8.0±0.1 | |||

| 1613 | 15.9±0.05 | 13.2±0.1 | |||

| 1908 | 19.1±0.05 | 8.0±0.1 | |||

| 1913 | 19.1±0.05 | 13.2±0.1 | |||

| 1916 | 19.1±0.05 | 16.0±0.1 | |||

| Note: Special type and size can be customized | |||||

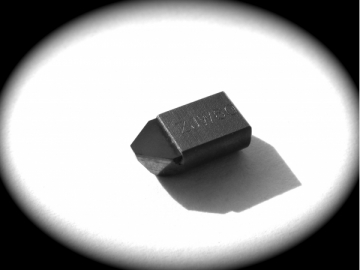

Material

The PDC cutter uses diamond powder and tungsten carbide.

Packaging

The PDC cutter is packaged in a plastic case/carton.

World is a PDC cuttermanufacturer and supplier, based in