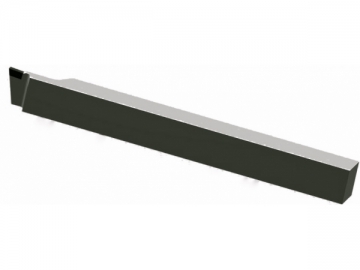

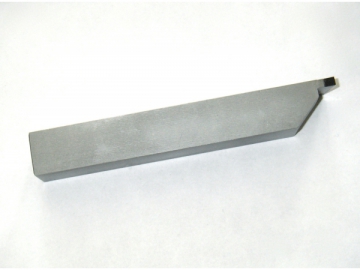

PCD/PCBN External Grooving Tools

PCD External Grooving Tool, PCBN External Grooving Tool

Features

1. The service life of welding the PCD/PCBN external grooving tool is 10 to 15times that of the average tungsten carbide grooving tool and coating grooving tool.

2. The processing precision of the PCD/PCBN external grooving tool can reach 3 micrometers.

3. The PCD/PCBN external grooving tool features small vibration of the blade. It can also avoid the easy breaking of the setscrew and the trouble of repeatedly adjustingthe tip.

4. We can manufacture welding PCD/PCBN external grooving tool of variousspecifications according to the need of our customers.

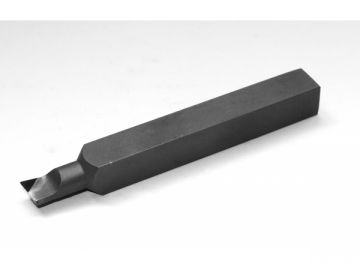

Application

The PCD external grooving tool is used to groove and cut various materials including copper, aluminum,copper alloy, aluminum alloy, tungsten carbide and nonmetal work pieces such as composite material.

The PCBN external grooving tool is used to groove and cut hardened steel, hard cast iron, grey cast iron and ironseries metal work pieces.

Technical Specifications

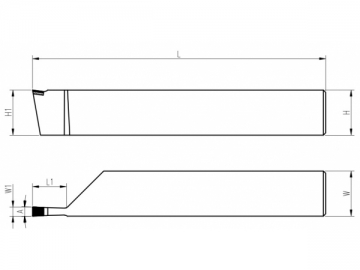

Specification of PCD/PCBN External Grooving Tool

| Drawings of the Grooving Tools | Dimension (mm) | ||||||||

| W1 | H1 | H | W/D | L | d | L1 | f | R | |

| 3 | 10 | 20 | 20 | 120 | 10 | 30 | 8 | 0.4 | |

| 3 | 10 | 20 | 20 | 120 | 10 | 30 | 8 | 0.4 | |

| 3 | 7 | 14 | D14 | 120 | 16 | 30 | 11 | 0.4 | |

| 3 | 10 | 20 | D12 | 120 | 16 | 30 | 11 | 0.4 | |

Material

The tool bit of the external grooving tools uses PCBN or PCD blanksmanufactured by world famous companies including Element Six (DeBeers, E6), DI(GE), ILJIN, SMITH, SUMITOMO and TOMEI. Thecutter arbor uses high quality tungsten carbide and tool steel.

World is a PCD external grooving tool manufacturer and supplier, based in