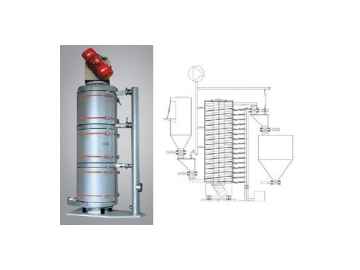

Vacuum Drying Machine

Vacuum Drying Machine

WorkingPrinciple and Features of the Vacuum Drying Machine

Pure water has the highest evaporation speed under boilingconditions. At normal pressure, pure water starts to boil at

The raw material is under static conditions during operation of the equipment,which is a benefit for maintaining the initial status of material. Intermittent operation can adjust process conditions at any time.

The FZG vacuum drying machine heating system is designed to tackle the problemof the return of condensed water. In addition, air suction is applied at theside to improve drying efficiency.

This equipment can be used for low temperature drying and solvent recovery, andthe heat source used can be steam, hot water, or heat conducting oil.

The vacuum drying machine is especially suited for materials that are easilyoxidized during drying.

Application ofthe Vacuum DryingMachine

The vacuum drying machine is suitable for drying heat sensitiveraw materials for the pharmaceutical industry, chemical industry, foodstuffindustry, electronic industry, Chinese traditional medicine industry, and more

Features ofthe Vacuum Drying Machine

It can achieve a faster drying speed at a lower temperature, makingit more energy efficient.

It can dry at a low temperature, and so can be used to dry heat-sensitive rawmaterials.

It can dry raw materials that contain solvents which need to be recovered.

Before drying, the vacuum drying machine can effect a disinfectant treatment,and during drying, no impurities can enter.

Process Flowsheet:

Technical Parameters of the Vacuum Drying Machine

| Style Name | YZG-600 | YZG-800 | YZG-1000 | YZG-1400 | FZG-10 | FZG-15 | FZG-20 |

| Inner size of chamber (mm) | Φ600×976 | Φ800×1320 | Φ1000×1530 | Φ1400×2080 | 1500x1040x1220 | 1500x1400x1200 | 1500x1800x1200 |

| outer size of chamber (mm) | 750×950×1050 | 950×1210×1350 | 1150×1410×1600 | 1550×1900×2150 | 1676×1700×1564 | 1676×2060×1564 | 1676×2500×1564 |

| Layers of support | 4 | 8 | 12 | 32 | 20 | 32 | 48 |

| Interval of layer (mm) | 85 | 100 | 100 | 100 | 120 | 120 | 120 |

| Size of trays (mm) | 310×600×45 | 640×460×45 | 640×460×45 | 640×460×45 | 640×460×45 | 640×460×45 | 640×460×45 |

| Qty of trays | 4 | 12 | 32 | 32 |

|

|

|

| Working pressure inside the pipe of support (Mpa) | ≤0.784 ( | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 |

| Operation Temp of support (℃) | 35~150 | 35~150 | 35~150 | 35~150 | 35~150 | 35~150 | 35~150 |

| Degree of vacuum inside the chamber when operation when idle (Mpa) | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 |

| Under the condition of -0.1Mpa and | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| When condenser is used, model and power of vacuum pump, kW | 2X-15 2kW | 2X | 2X | 2X | 2X | 2X | 2X |

| When condenser is not used, model and power of vacuum pump, kW | SZ-0.5 1.5kW | SZ-1 2.2kW | SZ-1 2.2kW | SZ-2 5.5kW | SZ-2 4.0kW | SZ-2 5.5kW | SZ-2 5.5kW |

| G.W (kg) | 250 | 600 | 800 | 1400 | 1400 | 2100 | 3200 |

Notes Regarding Ordering

When placing your order, please choose the vacuum drying machinesuited to the raw materials to be dried, such as, physical properties,beginning moisture, temperature, vacuum degree, amount to be dried, dryingtime, etc. The vacuum dryer is available in models for any of three heat sourceuses: steam type, hot water type, heat conduction oil.

The accessories used for vacuum drying system mentioned in OperationInstruments can be provided and installed by our factory. Please mention whenordering.

We can also provide specialized design, manufacture, and installation vacuumdrying machines services for the particular requirements of customers.

Our equipment comes with a guarantee of repair, replacement orrefund for substandard products, and we also supply spare parts, so you canfeel secure in our service.