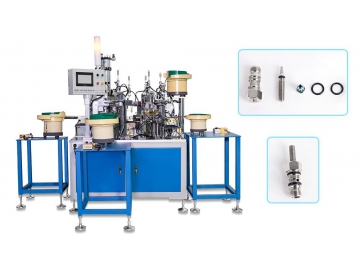

Mixed water ceramic valve core automatic assembly + vacuum inspection line

Request a Quote

Application

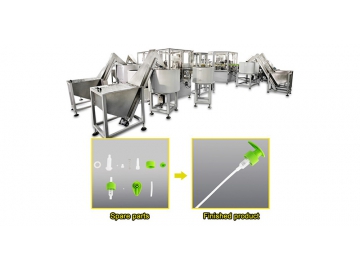

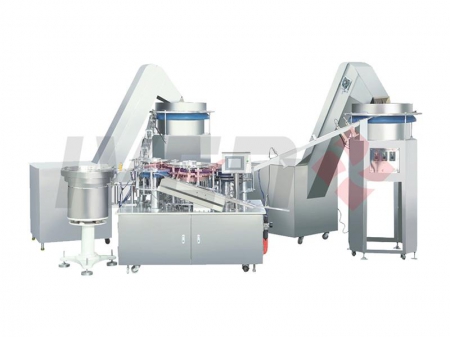

Composed of three machines in the following, our automated production machinery is designed for automated assembly and leak testing of mixer tap valve.

Details

Specifications

- Measurement Range: <1MPa

- Measurement Resolution: 0.001MPa

- Measurement Tolerance: 0.004MPa (slight difference between varying workpieces)

- Power: 1-2KW

- Assembly Machine Features

- Fully automatic or semi-automatic feeding method are both used in one machine

- Various items can be assembled

- Automatic oil filling, oil evening function

- Control the amount of oil filling, minimize the loss of consumables and reduce the product defect rate

- Automatic sorting direction controlled by a visual system for irregularly shaped samples

- Viscous products are automatically dispensed to prevent mixing

- Reduce labor costs while increasing production capacity and qualification rate

- Vacuum Testing Machine Features

- Can be used as a single machine or connected to an assembly machine to form a production line.

- Every process has uniform oil function

- 5 products can be tested simultaneously

- Pressure is applied for 8 seconds during each process

- Automatic and repeated hot and cold water direction opening and closing test method, this ensures vacuum detection is more reliable

- The automatic product shell vacuum test method can detect the quality of the inside of ceramic pieces to ensure that the product qualification rate exceeds 99.8%.

Please contact us for more details and video information.

Related products

Send Message

Most Recent

More

Other Products

Videos