8-Axis CNC Press Brake

Request a Quote

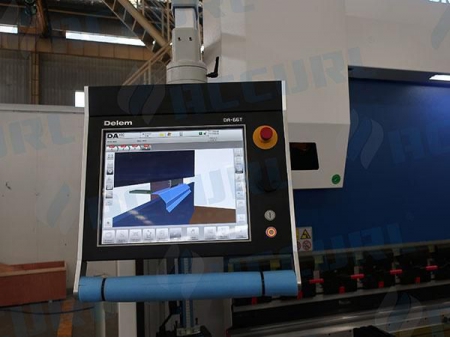

ACCURL® 8 axis CNC press brake features an automatic CNC crowning system for improved quality, a servo driven back gauge system for increased speeds, and a 3D capable graphical control unit to simulate bending sequences and collision points.

Features

- Provides a combination of performance, cost effectiveness and easy to use features

- Outstanding Value! Best brake for the money on the market.

- User friendly DELEM DA66T CNC control unit and Profile 3D software

- Precise bending results

- Tough construction with the same solid framework we use for all ACCURL 8-Axis CNC Press Brakes

- Large daylight opening allows the entire length of the machine to be put to optimal use

- Designed and built with the objective to help you achieve low cost manufacturing

- Standard 8 axis X1, X2 , R1 , R2 , Z1, Z2, Y1, Y2 for CNC Press Brake Machine

Standard Equipment

- Mono block, welded steel frame rigid to deflection and high tensile with ST44 A1 material.

- Delem DA66T 3D/2D graphical touch screen controller

- BGA-6 for Back gauge system with X1, X2, R1, R2, Z1, Z2 axis driven by AC servo with colored graphics.

- HOERBIGER servo hydraulic system.

- CNC controlled motorized anti-deflection system.

- Hardened and ground standard sectioned top and 4V-Die bottom tools (835 mm section).

- Easy to clamp tool holding system with upper and lower tools.

- Ergonomic user friendly, pendant control panel.

- Back light safety guards (category-4)

- Front side covers with safety switches.

- Synchronization of Y1 Y2 axis provided by linear encoders with 0.01 mm tolerances.

- Foot pedal suitable to CE regulation.

- Sliding front support arms with T slot and mm/inch rulers.

- Electrical panel with cooling system designed to meet CE standards & comprised of Siemens automatic and electrical equipment

Optional Equipment

- Graphical controllers; Cybelec ModEva RA Premium 3D with PC-RA Premium offline software, Delem DA-69T 3D graphical color controller with Profile T3D offline software.

- SICK C4000 advanced finger protections 14 mm (easy programmable Sick software with PC: Blanking, reduced resolution, cascade working etc.)

- Laser protection system for die area, LASERSAFE PCSS, AKAS LASER SAFETY IILC2000, Sick V 4000 (Camera based system), DSP electric laser safety.

- Laser angle measurement system, with Data-M cobra laser check system.

- Hydraulic and Dynamic-Hydraulic anti-deflection (crowning) features.

- ACCURL top tool clamping system. Hydraulic top and bottom tool clamping system.

- CNC controlled bending supports (AP1 AP2 axis).

- Hydraulic oil coolant and oil heaters.

- Automatic central lubrication system.

- Special throat depth (500,600,750 mm and above).

- Special top and bottom tools.

- Software options.

- Tandem applications.

- Tool cabinets.

Specifications

| Model(EURO PRO) | B1560 | B2580 | B32110 | B32135 | B32175 | B40175 | B32220 | ||

| Bending force | KN | 600 | 800 | 1100 | 1350 | 1750 | 1750 | 2200 | |

| Bending Length | mm | 1500 | 2500 | 3200 | 3200 | 3200 | 4200 | 3200 | |

| Between Columns | mm | 1100 | 2060 | 2700 | 2700 | 2700 | 3700 | 2700 | |

| Daylight | mm | 405 | 405 | 430 | 430 | 430 | 430 | 430 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Throat Depth | mm | 370 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 80 | 80 | 100 | 100 | 100 | 100 | 140 | |

| Down Speed | mm/min | 200 | 200 | 180 | 180 | 160 | 160 | 160 | |

| Pressing Speed | mm/min | 8 | 8 | 10 | 10 | 10 | 10 | 10 | |

| Return Speed | mm/min | 180 | 180 | 150 | 150 | 150 | 150 | 140 | |

| Back Gauge Stroke | mm | 500 | 600 | 800 | 800 | 800 | 800 | 800 | |

| Outline Size | L | mm | 1825 | 2825 | 3500 | 3550 | 3500 | 4500 | 3500 |

| W | mm | 1650 | 1650 | 1650 | 1650 | 1650 | 1650 | 1730 | |

| H | mm | 2300 | 2350 | 2650 | 2700 | 2700 | 2750 | 2900 | |

| Weight | kg | 4600 | 5600 | 8000 | 9500 | 10000 | 12000 | 13200 | |

The best bending results! Users can bend longer and deeper parts with the standard Euro Pro B series!

Detailed Pictures

- CNC 8 Axis Press Brake Machine with DELEM DA-66T 3D2D graphical CNC

- DELEM DA66T CNC System for Press Brake

- DSP Lazersafe for Accurl CNC Press Brake

- HOERBIGER servo hydraulic system

- Hydraulic cylinder with German Trumpf technology

- Press Brake with CNC Back Gauge for X1 X2 R1 R2 Z1 Z2-axis