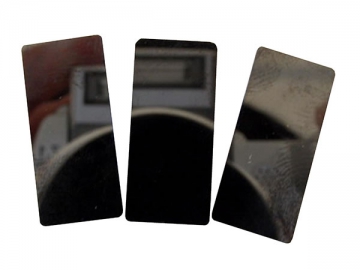

CVD Diamond Bars

Application:

CVD diamond bar can be made into single and multi-point dresser, polishing tool, diamond dressing roller, jewelry processing tool, etc.

Description:

CVD diamond is an idea material to replace natural diamond in future. Truing and dressing are playing a vital role in today’s grinding process, and their purposes are to remove dull grits, improve wheel sharpness and concentricity and shape of the wheels. Being the largest manufacturer in China, we offer a wide range of CVD diamond dresser bars in diamond dressing field.

Features:

Compared with mono diamond and PCD, CVD diamond has many advantages in dressing applications.

1. Excellent in hardness, sharpness and thermal stability.

2. Unbeatable availability in shape and size.

3. Highly consistent of dressing parameter, the processing quality is controlled.

4. This dressing tool is greatly simplified manufacturing process.

| Specifications | Tolerances | Applications |

| 0.6*0.6*0.6 | +/- 0.05mm | Dressing Rollers |

| 0.8*0.8*0.8 | ||

| 1.0*1.0*1.0 | +/- 0.08mm | Single and Multi-point Dressers |

| 1.2*1.2*1.2 | ||

| 1.5*1.5*1.5 | +/- 0.10mm | |

| 1.8*1.8*1.8 | ||

| 2.0*2.0*2.0 | ||

| 2.2*2.2*2.2 | ||

| 2.5*2.5*2.5 |

| 5.0*0.2*0.2t | 8.0*0.5*0.5t | 3.0*1.0*0.8t | 5.0*2.0*1.0t | 5.0*1.3*1.3t |

| 2.5*0.5*0.3t | 5.0*1.0*0.5t | 2.5*1.3*0.8t | 4.0*1.5*1.0t | 2.0*1.5*1.5t |

| 3.0*1.0*0.3t | 2.0*0.6*0.6t | 5.0*0.9*0.9t | 5.0*1.1*1.1t | 4.0*1.5*1.5t |

| 10.0*3.5*0.3t | 5.0*0.7*0.7t | 3.0*1.0*1.0t | 1.5*1.2*1.2t | 4.0*2.8*1.5t |

| 2.0*0.4*0.4t | 1.5*0.8*0.8t | 8.0*1.0*1.0t | 2.0*1.2*1.2t | 2.0*2.0*1.8t |

| 5.0*0.6*0.4t | 4.5*0.8*0.8t | 10.0*1.0*1.0t | 5.0*1.2*1.2 | 3.0*2.0*2.0t |

| 1.5*0.5*0.5t | 10.0*0.8*0.8t | 3.0*1.5*1.0t | 4.0*1.3*1.3t | 3.0*3.0*2.5t |

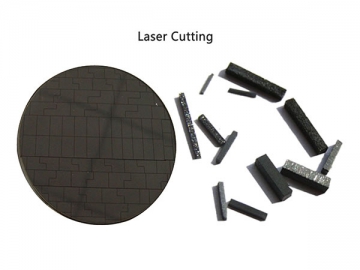

Notes:

The letter T indicates the thickness of CVD diamond materials, say from the nucleation side to the growth side.

The above is only a short list of standard sizes available, additional sizes like triangle and trapezoid are also available upon request.

Normally, Worldia has several hundred specifications of CVD diamond logs in stock.

The tolerance of standard dresser log product is +/- 0.05mm, while we can control the tolerance within +/- 0.025mm upon request.

The production lead time is normally 4 to 8 days, and some of the items may be shipped within 2 work days upon the payment is confirmed.

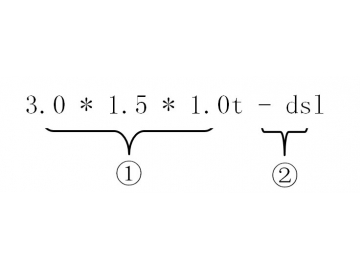

Ordering Instructions

①Please specify the specifications in the form of length*width*thickness, and to avoid confusion possible, please also remember to mark the thickness with the letter T.

②This part indicates whether the CVD diamond material should be lapped before laser-cut into dresser logs.

a)dsl means they should be Double Side Lapped, e.g. 2.0*0.6*0.6t-dsl

b)ssl means they should be Single Side Lapped, e.g. 3.0*0.8*0.8t-ssl

c)Leave it blank if the materials are not lapped, or if there is no requirement in this aspect.

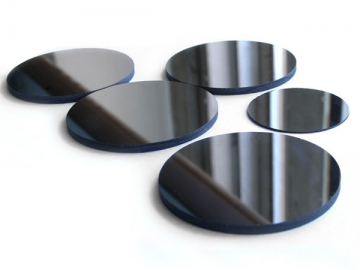

Packaging:

Our CVD diamond bar use plastic case for packing.

The self-supported diamond die blank is packaged in a plastic case/carton.

Quality Control:

We have dedicated team of quality control and precise equipment to keep good and stable performance for our products and processing services.

OEM/ODM Service:

We can customize CVD diamond dresser bar as you wish.

Custom-made products would be available according to customers’ requirements.

Contact:

As a specialized CVD diamond products manufacturer and supplier in China, Worldia are devoted to be the leading company in area of CVD diamond products manufacturing, and we are committed to provide our customers with cost effective, high performance and high standard CVD products.

About Us:

Worldia is a professional manufacturer of glass cutting tools, PCD/PCBN cutting tools, diamond die blanks, saw blades and CVD diamond products. Depend on the creed of “we do what the customers need”, as long as we could offer to our customers whatever for the quantity and requirement of products, we will try our best to complete. Worldia would like to establish business relationships with friends all over the world to promote the advancement of the super hard material industry.