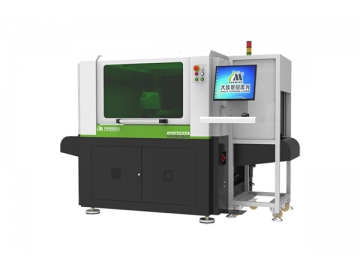

Automatic Sole Glue Sprayer

Product Feature

1.Imported high-precision 3D laser scanning system is capable of scanning the sole dimensions at a high speed with a high precision.

2.According to the sole dimensions and glue specifications, YUEMING patented sole glue spray software and control system can automatic create the glue spray path without manual intervention or programming.

3.Glue spray system features simple operations. Soles of different sizes can adopt the same set of specifications.

4.Two five-axis robot arms work together to achieve a processing efficiency of 240 pairs of soles per hour.

5.UV inspection and glue activation and curing functions are featured to ensure the high spray quality.

6.Humanized design: easy operation, clog resistant nozzle, easy removal of glue residue in the transmission mechanism.

7.According to the specific needs of customers, several customization services are available, including automatic material loading and unloading, production management functions, interface to MES development and etc.

Technical parameter

| Product | Automatic sole glue sprayer |

| Model | AMS-R5-FB |

| Contour inspection | 3D laser scanning |

| Spray circulation | < 10s/pair |

| Conveyor speed | 0-500mm/s |

| Air pressure | >0.4MPa |

| Dimensions | L2560xH1630×W1500 |

| Working environment | 0-45℃ Humidity≤ 80%, no condensation |

| Gross power | ~3KW |

| Power supply | 220V/50Hz |

| Weight | 1000Kg |

Process

1.Sole feeding

Put the soles in the entrance frame.

2.Data collection

Sole contour is automatically inspected by 3D laser scanning system to collect the data.

3.Data transmission

Already scanned data will be uploaded to the YUEMING patented sole glue software.

4.Specifications generation

The program-free software automatically generates all the specifications.

5.Sole spraying

Two precise robot arms work together to spray glue on left and right sides of sole.

6.Process finishing

According to your requirements, automatic material loading and unloading can be customized.