Ceramic Lining Ball Mill

Request a Quote

Application

The ceramic lining ball mill is equipment used to grind various ores and other materials. It reduces iron pollution, making it suitable for use in ceramics, oil paint, pigment, chemical engineering, medicine, paints and more. The grinding modes include wet and dry type.

Applicable materials

Limestone, calcite, coal ash, desulphurization of calcium carbide, kaolin, calcium carbonate, coal gangue, gypsum, water granulated slag, slag powder, coal dust, bentonite clay, barite, talcum and refractory materials can all be ground using the ceramic lining ball mill.

| Type | Load capacity (t/ each time) | Cylinder speed (r/min) | Reference power (KW) | Liner material | |

| 600×700 | 0.05 | 50 | 2.2 | Ceramics, silica, rubber, metal | |

| 800×600 | 0.075 | 42 | 3 | | |

| 900×1200 | 0.2 | 38.5 | 5.5 | | |

| 1300×1500 | 0.5 | 33 | 7.5 | | |

| 1500×1800 | 1.2 | 28.5 | 11 | | |

| 1800×2000 | 1.5 | 24 | 15 | | |

| 2600×2800 | 5 | 16.5 | 37 | | |

| 3000×3800 | 10 | 14.5 | 57.2 | | |

| 3200×4600 | 15 | 13.5 | 75 | |

- Driving section: mainly composed by reduction gears, pinion drive gears, electrical engine, electronic control and more.

- Bound system: The ball mill and classifier compose a closed system that will move under the negative pressure with no dust. It features a maximum energy saving performance by matching the actuator and energy consumption in the grinding process.

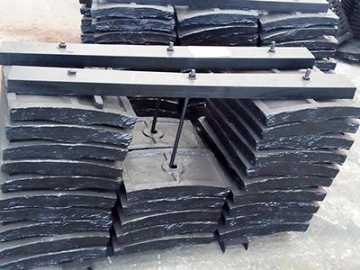

- Ceramic liner and ceramic ball: they are known for their wear resistance, shock resistance, high temperature resistance, acid and alkali resistance and pull-off avoiding.

Related

grinding plant, industrial grinder, powder milling equipment

grinding plant, industrial grinder, powder milling equipment

Related products

Send Message

Most Recent

More

Other Products

Videos