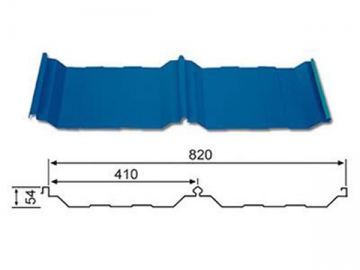

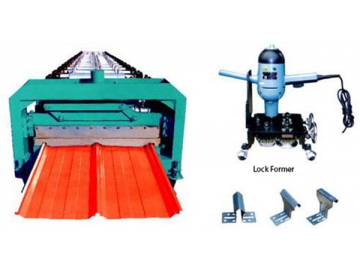

Concealed Roof Panel Roll Forming Machine

Request a Quote

Specifications of the concealed roof panel roll forming machine

| Suitable material | Color steel sheet, thickness from 0.3mm to 0.7mm |

| Working speed | Approximately 8-15m/min |

| stress | 235MPa, 345MPa, 550MPa. |

| Power | Main motor power: 5.5 Kw (Depends on design) |

| Hydraulic station power: 3Kw (Depends on design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter, pressing die | Cr12 mold steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, Roller grinder milling. |

| Controlling system | PLC |

| Total weight of machine | Approximately 50,000 KGS |

| Machine's size | Approximately 8m×1.3m× 1.5m |

Advantages

1. Anti-rust roller: The anti-rust roller is produced using a CNC machine. It is plated with hard chrome to protect the surface’s shine and ensure the strength.

2. Heat treatment: Heat treatment for the cutting frame removes steel stress and avoids deformations.

3. Cutter blade: the Cr12 mold steel blade undergoes a quenched treatment, and has a long service life.

4. High precision: The shafts for the rollers are tooled using a grinding machine. Rollers are CNC processed to ensure a precision performance.

5. Automatic PLC: The imported PLC utilizes a touch screen, inverter and transformer.

Related products

Send Message

Most Recent

More

Other Products

Videos