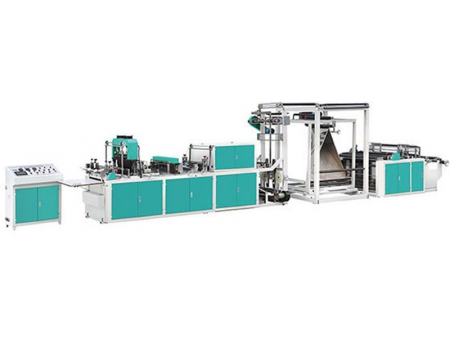

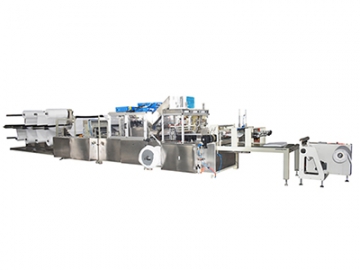

Ultrasonic Non-woven Bag Sealing Machine, XD-HB1000

Bag Sealer/ Ultrasonic Sealer/ Bag Making Machine

Main Introductions

The ultrasonic non-woven bag sealing machine can cut and sew non-woven films for the production of items such as medical gowns and shoe covers with strong seams and beautiful designs.

Specifications

1. Imported piezoelectric chip, for strong and stable output

2. Pattern wheel made of special alloy steel, wear-resistant and long-lived welding head

3. Removable lace mold, eccentric adjustment, high flexibility and speed

4. Fast operating speed, excellent effects and quality guarantee

5. Assembled from full set of imported components, offering stable performance

Functional Description

1. Ultrasonic processing and special steel wheel, without damaging the fabric edge or producing burrs

2. Easy replacement of pattern wheel with pattern depending on customer needs

3. Manufacturing without preheating, capable of continuous operation

4. Sewing: Various fabrics can be sewed up directly for waterproofing without needle and thread thanks to the ultrasonic sealer.

5. Lace: Various leathers/fabrics can be pressed into any pattern with the ultrasonic unit without burr.

6. Gold stamping: Fast and effective gold stamping can be given to various leathers/fabrics with the ultrasonic unit.

7. Bound edge: Bound edge treatment can be given to various leathers/fabrics with the ultrasonic unit.

| Model | HB1000 |

| Power | 220±5V, 50Hz 6A |

| Power Input | 1.5kw-2.5kw(adjustable) |

| Power Output | 20KHz |

| Speed | 0-15m/min |

| Effective Width | 90mm |

| Weight | 140KG |

| Dimension | 1300mm×650mm×1000mm |