Automatic Pallet Wrapper & Strapper

In factories, warehouses and packaging workshops, pallet wrapping machines and pallet strapping machines are frequently used pallet packaging solutions for various industrial packaging applications. Particularly, in corrugated cardboard manufacturing plants, the use of pallet wrapper and pallet strapper can help cardboard manufacturers increase working efficiency while reducing the risk of packaging problems that often occur when the pallet is wrapped manually.

Taiyang offers a range of automatic pallet wrapping and strapping machines that can satisfy your corrugated board packaging needs. Please get in touch with our engineers if you want more details.

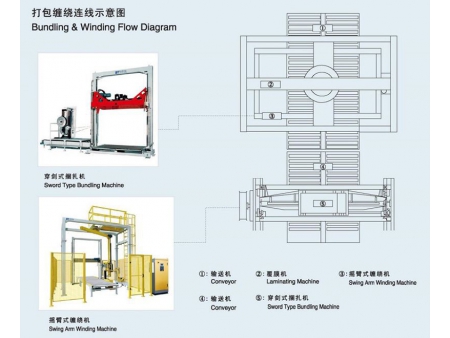

Stacks of corrugated cardboards get reliably bundled and secured for transport here. Two modules: automatic pallet strapper and automatic wrapper are deployed in order, connected with conveyor, to perform a full-auto and consistent stacking - feeding - bundling - film wrapping process.

Advantages

- We can offer the most suitable configuration according your certain situations;

- According to your production line set-up, we can offer you the optimal arrangements of automatic warping and strapping system deployment.

-

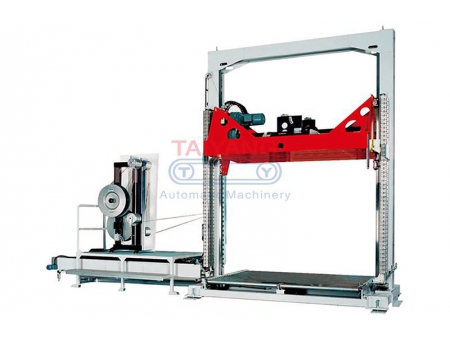

To automatically strap stack or cargo on its pallet transversely and longitudinally with the control of high-performance PLC. The strapping is performed with PET strap, and the process is suitable for strapping both stacks of loads or cargo loaded in container.

Power supply: 380V/50HZ 2000W/5A

Strapping type: 1 ~ multi parallel straps, automatic/manual -

Suitable for wrapping very heavy or light loads that may create instability. Automated control involves the full wrapping processes including load detection, packaging, centering, wrapping, conveying, etc.

Power supply: 2.2kw/380V

Pallet size (L*W): L1200*W1200 mm (customizable) -

Power supply: 1.55kw

Pallet size(L*W): 1200*1200 mm (customizable)

Maximum load height: 2200 mm (customizable)

Wrapping material: LLDPE stretch wrap film, width: 500mm, thickness: 17~30um

Production speed: 20-40 loads/hour -

To perform stretch wrapping on light and loose loads. Top press is available during wrapping, in case the load is slanted. The top press is powered by pneumatic drive or electric motor drive.