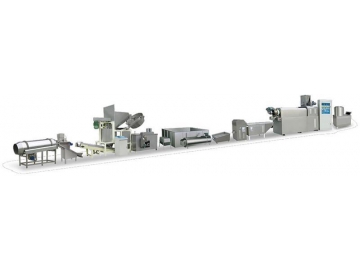

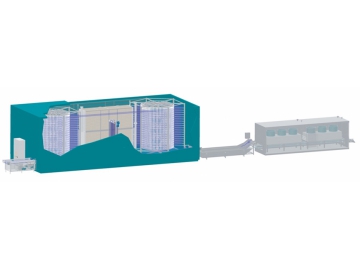

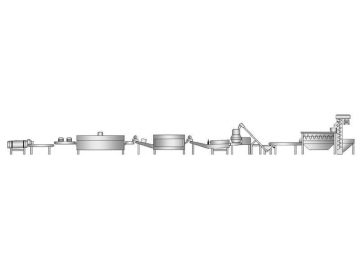

Potato Chips, French Fries Processing Line

Introduction

The potato chips and french fries processing line of Luerya is an outstanding piece of food production machinery and consists of an automatic, manual lifting system, conveying system, slag discharge system, heating system, and oil circulation system.

| Model | Installed Power | Water Consumption | Heating Oil Boiler | Throughput | |

| YS-100 Processing Line | 30-60KW | 3-8T/h | 30-40 million kcal | 100kg/h | |

| YS-200 Processing Line | 60-120KW | 6-16T/h | 60-80 million kcal | 200kg/h |

Process

Raw material washing → Shelling → Trim → Blanching → Dehydration → Deep frying → Deoiling → Filtrating → Seasoning → Packaging

Main equipment

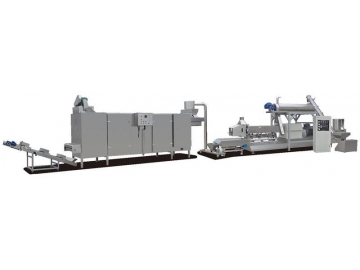

SX food process extruder with twin screw

The food process extruder with twin screw produced by Luerya consists of a feeding system, extrusion system, cut system, heating system, drive system, cooling system and control system. The cut system is controlled by frequency controller and it is highly automated.

- Components: imported parts

- Control system: it is designed with automatic equipment and controlled by computer programs

- It is easier to set parameters like humidity, pressure and temperature.

- Throughput: 400-500kg/h

| Model | Installed Power | Actual Consumption | Main Power | Throughput | Dimension | |

| SX90-II | 115.9KW | 55KW | 90KW | 800-1000kg/h | 6.0×2.5×3.5m | |

| SX85-II | 78KW | 55KW | 55KW | 300-500kg/h | 4.0×1.2×3.0m | |

| SX65-I | 60KW | 45KW | 30KW | 150-200kg/h | 3.5×1.0×1.8m | |

| SX65-IIIA | 35KW | 28KW | 22KW | 120-150kg/h | 2.5×1.0×1.8m | |

| SX65-IIIB | 35KW | 28KW | 22KW | 120-150kg/h | 3.5×1.0×1.8m |

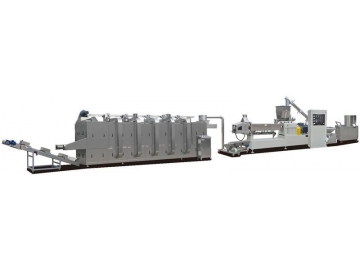

LXZG-2500 automatic continuous food frying equipment

Automatic continuous food frying equipment consists of a wire mesh belt conveying system, automatic lifting system, automatic filtering system, oil temperature automatic control system, automatic oil filling system, heating system. It can product full automatically heated by coal, gas, oil, electric, etc. It is used to fry puffed food, cooked wheaten food, meat product and some other raw materials.

- Palm oil is recycled by oil pump, so oil temperature can be stable

- It is designed with an automatic filtration system to clear scrap timely. So that the oil can keep clean and the fry quality can be good.

- The fryer is designed with an automatic hoisting system. So it can be cleaned and maintained easily.

- It has large throughput and low energy consumption.

| Model | Input Voltage | Installed Power | Throughput | Dimension | |

| LXZG-2500 | 380v 50Hz | 2.5KW | 100-200kg/h | 5.0×2.0×3.0m | |

| LXZG-5000 | 380v 50Hz | 110KW | 1500-2000kg/h | 7.0×2.0×3.0m | |

| YZD-II | 380v 50Hz | 41KW | 100-150kg/h | 4.55×1.98×2.9m | |

| YZY-II | 380v 50Hz | 5.0KW | 60kg/h | 4.55×1.98×2.9m |

Index

food processing equipment, commercial food machines, food manufacturing line, puffed food machines