Mining Fiber Optic Cable

Description

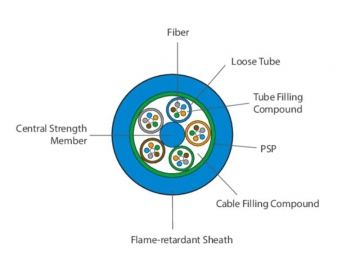

Mining fiber optic cables are a flame retardant communication optic fiber cable usually used in coal mines, gold mines, iron mines and other underground mines. We provide MGTS mining fiber optic cable to our customers, and the production process is as follows. We first insert the 250um optic fiber into a loose tube made of high modulus material and then fill the loose tube with a waterproof compound. Loose tubes will then be twisted around the central strength member, and depending on application needs, the strength member will be coated with PE when the fiber optic cable features special fiber counts. Finally, a round cable core is wrapped with PSP and sequeezed in a flame retardant sheath, then filled with a water blocking compound.

Standard

| Type (increase by two fibers ++) | Fiber count | Cable diameter (mm) | Cable weight (kg/km) | Allowable tensile strength (short/long term) (N) | Allowable crush resistance short/long term (N/100mm) | Bend radius dynamic/ static (mm) |

| GYXTW 2-12 | 2-12 | 8.9 | 100 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA 8-12 | 8-12 | 10.6 | 124 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA 14-18 | 14-18 | 12.0 | 147 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA 20-24 | 20-24 | 12.0 | 150 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA 26-30 | 26-30 | 15.0 | 207 | 1000/3000 | 1000/3000 | 10D/20D |

| Storage/Operating Temperature: -40℃ to +70℃ | ||||||

| G652 | G655 | 50/125UM | 62.5/125UM | ||

| Attenuation (+20℃) | @850nm | ≤0.30db/km | ≤3.3db/km | ||

| @1300nm | ≤1.0db/km | ≤1.0db/km | |||

| @1310nm | ≤0.36db/km | ≤0.40db/km | |||

| @1550nm | ≤0.22db/km | ≤0.23db/km | |||

| Bandwidth (grade A) | @850 | ≥500MHz.km | ≥200MHz.km | ||

| @1300 | ≥1000MHz.km | ≥600MHz.km | |||

| Numerical aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| Cutoff wavelength of optic fiber | ≤1450nm | ||||

| Application: duct fiber optic cable | |||||

- The mining fiber optic cable has a great mechanical property.

- The loose tube material features a great hydrolysis resistance and higher strength.

- The special factice filled in the cable protect the fiber.

- The sheath is made of a flame retardant material.

- The mining fiber optic cable has a great stress tolerance and flexibility.

- The tight cable structure is designed specifically to prevent the sheath retraction.

The following measures can protect the fiber from water.

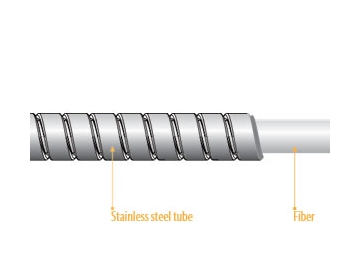

- The mining fiber optic cable use a steel wire as the central strength member.

- The special waterproof compound is filled in the loose tube.

- The PSP can improve the moisture proof of cable.