Directional Drilling Fly Cutter Reamer

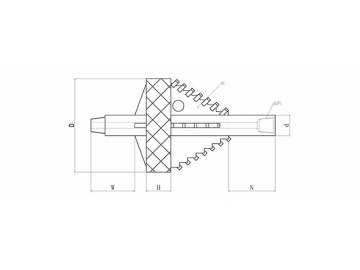

Directional drilling fly cutter reamer is equipped with a circle of centralizing ring outside the three wing plates. The centralizing ring is used as the reinforcing rib of wing plates and also works as centralizer. The cutting edges on wing plates and centralizing ring are punctation distributed and the design principle is similar to that of winged reamer. The cutting edges of wing plate adopt stepped stratified cutting and they are short and punctation distributed, so the rotation resistance is decreased. The opening structure makes it easy for drilling fluid and drilling chips to go across the reamer bits and it has the advantages of high reaming speed, good straightening ability and convenient repair. Directional drilling fly cutter reamer shows strong ability to overcome obstacles and it can get through smoothly even if meeting large construction waste such as stones. However, generally specialized hole clearing process should be carried out after reaming. It's generally suitable for reaming in hard soil layer.

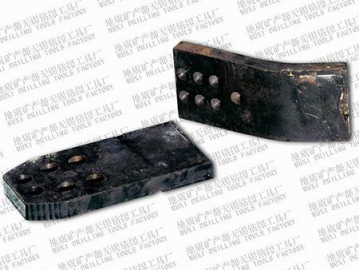

Main componentsCore shaft, 16Mn steel sheet, carbide bit

SpecificationThe directional drilling fly cutter reamers produced in our factory have specifications of φ300mm~φ1500mm. Threads connected to core shaft can be matched according to users' requirements.

Product maintenanceClean the mud and sand pasted on bit surface every time after back reaming process and clear the nozzle hole on core shaft to ensure the smooth passing of mud during reaming. Cool and clean the cutting edges. Meantime, check the wear of core shaft connected threads and the conditions of cutting edges of wing plates and centralizing ring. Pay attention and don't collide or heavily press when transporting and stacking in order not to damage cutting edges. Coat thread dope and screw thread protector on threads.