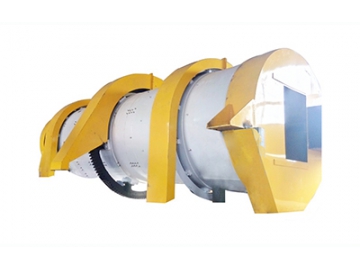

Granulation Drum

Our granulation drum is fitted with either special rubber-made lining or acid-resistant stainless steel-made lining, which are able to withstand corrosion and preserve heat. The linings will prevent materials from clinging to themselves. With the linings, surface of pellets will be smoothed and knotted particles will be removed. The drum eliminates the traditional scraper. The granulation drum features high-strength pellets, high quality, delicate appearance, corrosion resistance, low energy consumption, high capacity, long service time and easy operation and maintenance.

Generally, raw material enters the drum and then rotates and rolls with the rotation of the drum. The material will be made into pellets with certain temperature and humidity. The final pelletizing efficiency is about 70%. Some undersized particles will returned to the drum for further granulation.Sometimes, steam will be used to increase the temperature of the material. In this way, the material will contain less water after being pelletized.

The granulation drum is suitable for production of compound fertilizers. First, bunch of materials should be fed into the drum which include steam, gaseous ammonia, phosphoric acid or nitrogen liquid, phosphorus and ammonia slurry and calcium carbonate slurry. Then they will be heated and react with each other in the drum to produce compound fertilizer pellets. In other cases, a small amount of water will be added into the drum to be blended with these materials. At this time, cold granulation for compound fertilizer will be accomplished

Technical Parameters| Model | Drum | Capacity | Dimension | Weight | ||||

| Inclination | Inner Diameter | Length | Rotaing Speed | Power | Length × Width × Height | |||

| ° | Mm | Mm | r/min | Kw | t/h | Mm | T | |

| 2-2.5 | 1400 | 5000 | 14 | 7.5 | 3-5 | 5000×1950×2100 | 8.5 | |

| 2-2.5 | 1600 | 6000 | 11.5 | 11 | 5-8 | 6000×2100×2400 | 12.0 | |

| 2-2.5 | 1800 | 7000 | 11.5 | 18.5 | 8-10 | 7000×2200×2800 | 18.5 | |

| 2-2.5 | 2000 | 8000 | 11 | 22 | 10-15 | 8000×2600×3200 | 22.0 | |

| 2-2.5 | 2200 | 10000 | 10.5 | 30 | 15-20 | 10000×2800×3400 | 28.0 | |

| 2-2.5 | 2400 | 10000 | 9 | 37 | 20-25 | 10000×3220×3900 | 36.0 | |

| 2-2.5 | 2600 | 10000 | 8.3 | 45 | 25-30 | 10000×3500×4200 | 42.0 | |