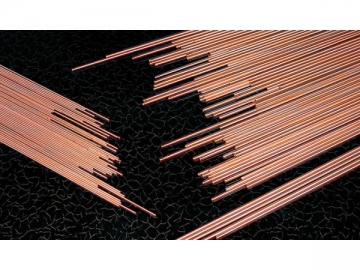

Free Machining Brass

Categories: Bar & Wire production-Brass Alloy Material

Name: Free Machining Brass

Number: C3602、C3603、C3771、C3604、C3605、HPb59-1、HPb58-3

Alloy Features

Minimal damage on tools during material processing;

Processing efficiency;

Outstanding straightness :< 0.3mm/m;

Good effects for hot forging, cold heading and riveting;

Long service life;

Ovality, high tolerance, consistency ;

| Item | Specification | |||

| ASTM | DIN | JIS | GB | |

| C36000 | CuZn36Pb3 | C3602 | HPb62-3 | 1.0-120mm |

| - | - | C3603 | - | |

| C37700 | CuZn39Pb2 | C3771 | HPb61-1 | |

| C38000 | CuZn39Pb3 | C3604 | HPb60-2 | |

| C38500 | CuZn40Pb3 | C3605 | HPb59-3 | |

| C37000 | CuZn40Pb2 | C3710 | HPb59-1 | |

| - | - | - | HPb58-3 | |

Characteristics

Excellent cutting, drilling performance, able to process by hot forging, cold heading and riveting with high strength, good toughness and corrosion resistance. Excellent discoloration resistance.

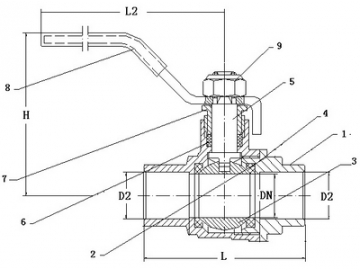

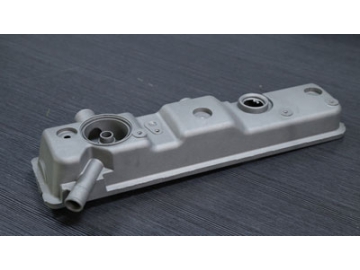

Application

The metal alloy is suitable for automatic lathes, CNC lathe processing products, such as hardware, electrical connectors and standard industrial connectors.

| Articles | Chemical composition ( wt%) | Total Impurity( wt%) | |||||

| GB/QB | DIN/ASTM/JIS | Cu | Pb | Zn | Fe | Sn | |

| C3602 | JIS C3602 | 59.0-63.0 | 1.8-3.7 | REM | ≤0.5 | Fe + Sn≤1.0 | - |

| C3603 | JIS C3603 | 57.0-61.0 | 1.8-3.7 | REM | ≤0.35 | Fe + Sn≤0.6 | - |

| C3604 | JIS C3604 | 57.0-61.0 | 1.8-3.7 | REM | ≤0.5 | Fe + Sn≤1.0 | - |

| C3605 | JIS C3605 | 56.0-60.0 | 3.5-4.5 | REM | ≤0.5 | Fe + Sn≤1.0 | - |

| C3771 | JIS C3771 | 57.0-61.0 | 1.0-2.5 | REM | Fe + Sn≤1.0 | - | |

| HPb59-1 | - | 57.0-60.0 | 0.8-1.9 | REM | ≤0.5 | - | ≤1.0 |

| HPb58-3 | - | 57.0-59.0 | 2.5-3.5 | REM | ≤0.5 | - | ≤1.2 |

| Articles | bar | wire | ||||||||

| Temper | Specification (mm) | Tensile Strength (MPa) | Elongation (%) | Hardness | Temper | Specification (mm) | Tensile Strength (MPa) | Elongation (%) | Hardness | |

| HPb63-3 | Y(H) | 5-15 | ≥490 | ≥3 | - | Y(H) | 0.5-2 | 390-610 | ≥3 | - |

| > 15-20 | ≥450 | ≥8 | > 2-4 | 390-600 | ≥3 | |||||

| > 20-30 | ≥410 | ≥10 | > 4-6 | 390-590 | ≥4 | |||||

| Y2 (1/2H) | 5-20 | ≥390 | ≥10 | Y2 (1/2H) | 0.5-6 | 570-735 | - | |||

| > 20-60 | ≥360 | ≥14 | ||||||||

| H62F | Y(H) | 2-20 | ≥380 | ≥12 | - | Y2 (1/2H) | 0.5-2 | 390-590 | ≥8 | - |

| > 2-4 | 390-590 | ≥10 | ||||||||

| > 20-60 | ≥340 | ≥15 | > 4-6 | 370-570 | ≥12 | |||||

| > 6-10 | 350-560 | ≥15 | ||||||||

| HPb59-1 | Y2 (1/2H) | 1-5 | ≥450 | ≥8 | - | Y2 (1/2H) | 0.5-4 | 390-590 | - | - |

| > 5-20 | ≥420 | ≥10 | > 4-10 | 360-570 | ||||||

| > 20-40 | ≥390 | ≥12 | Y(H) | 0.5-4 | 490-720 | |||||

| > 40-60 | ≥370 | ≥16 | > 4-10 | 400-640 | ||||||

| C3501 | - | - | - | - | - | O | > 0.5 | ≥295 | ≥20 | - |

| 1/2H | 0.5-12 | 345-440 | ≥10 | |||||||

| H | 0.5-10 | ≥420 | - | |||||||

| C3601 | 0 | 6-75 | ≥295 | ≥25 | - | 0 | 0.5-10 | ≥315 | ≥20 | - |

| 1/2H | 6-50 | ≥345 | - | ≥HV95 | 1/2H | 0.5-10 | ≥345 | - | - | |

| H | 6-20 | ≥450 | - | ≥HV130 | H | 0.5-10 | ≥345 | - | - | |

| C3602 | F | 6-75 | ≥315 | - | ≥HV75 | F | 0.5-10 | ≥345 | - | - |

| O | 6-75 | ≥315 | ≥20 | - | O | 0.5-10 | ≥365 | - | - | |

| C3603 | 1/2H | 6-50 | ≥365 | - | ≥HV100 | 1/2H | 0.5-10 | ≥365 | - | - |

| C3604 | H | 6-20 | ≥450 | - | ≥HV130 | H | 0.5-10 | ≥450 | - | - |

| C3605 | F | 6-75 | ≥335 | - | ≥HV80 | F | 0.5-10 | ≥420 | - | - |

| C3771 | F | 6-75 | ≥315 | ≥15 | - | F | 0.5-10 | ≥365 | ≥10 | - |

| Y(H) | 2-5 | ≥490 | - | - | Y(H) | 0.5-1 | 520-735 | - | - | |

| > 5-25 | ≥450 | - | - | > 1-6 | 440-710 | - | - | |||

| > 25-50 | ≥420 | - | - | > 6-10 | 410-610 | - | - | |||

| Articles | Temper | Specification | Tensile Strength (Mpa) | Elongation (%) | Hardness |

| HPb59-1 HPb58-2 HPb58-3 C3604 C3605 C3771 | Y2 (1/2H) | S3-S5 > S5-S20 > S20-S40 | ≥450 ≥420 ≥390 | ≥8 ≥10 ≥12 | - - - |

| ≥8 ≥10 ≥12 | S3-S5 > S5-S20 > S20-S40 | ≥480 ≥450 ≥420 | - - - | - - - | |

| C3501 360 C3601 C3002 C3603 | Y2 (1/2H) | S3-S5 > S5-S20 > S20-S40 | ≥420 ≥390 ≥360 | ≥10 ≥12 ≥14 | - - - |

| Y(H) | S3-S5 > S5-S20 > S20-S40 | ≥450 ≥420 ≥390 | - - - | - - - | |

| C3501 360 C3601 C3002 C3603 | Y2 (1/2H) | a3-a5 > a5-a20 > a20-a40 | ≥400 ≥360 ≥340 | ≥10 ≥12 ≥14 | - - - |

| HPb63-3 H62 H63 | Y2 (1/2H) | a3-a5 > a5-a20 > a20-a40 | ≥390 ≥360 ≥340 | ≥12 ≥14 ≥15 | - - - |

| HPb59-1 HPb58-2 C3601 C3602 C3603 C3604 C3605 360 C3771 | Y2 (1/2H) | (2-4)×(5-12) (4-8)×(6-15) (8-10)×(9-20) | ≥400 ≥380 ≥350 | ≥10 ≥12 ≥14 | - - - |

| HPb63-3 H62 H63 | Y2 (1/2H) | (2-4)×(5-12) (4-8)×(6-15) (8-10)×(9-20) | ≥400 ≥380 ≥350 | ≥10 ≥14 ≥15 | - - - |