LLW Horizontal Worm Screen Centrifuges

Main Features of LLW Horizontal Worm Screen Centrifuge

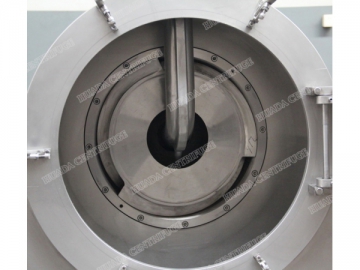

1. Main parts of our horizontal filtration centrifuge, such as basket and scroll, are made from top-ranking stainless steel and titanium alloy.

2. Conical angle is available as 10°, 15° and 20° for your selection.

3. Specialized metal screen comes with thickness up to 1.0mm to prolong service life.

4. Variable frequency drive control allows for stepless adjustment on rotation speed.

5. Continuous workflow covers feeding, separation, washing, dewatering and discharge, resulting in exceptional processing capacity.

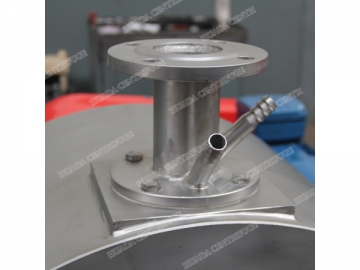

6. Independent lubrication system provides simple yet efficient performance.

7. Our food separation equipment is endowed with multi-protections to ensure reliable operation, including rotation speed detection, over-vibration protection as well as motor overheat and overload protection.

8. Built-in washing pipe is available in this chemical separation equipment, whereby cake can be washed while being filtered. Thin-layer washing method is responsible for impressive washing effects and low washing liquid consumption.

9. Steam pipe can be placed at the rear side of basket so as to clean crystallized materials at high temperature.

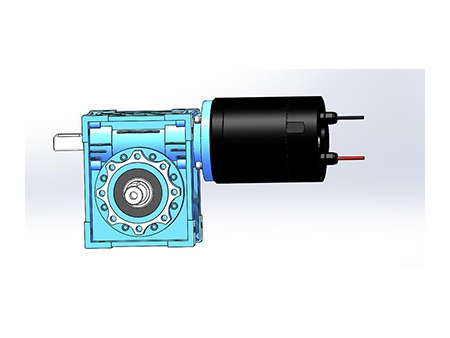

10. Scroll differential gear on our solid-liquid separation equipment falls into two choices that are mechanical mode and hydraulic mode. As for materials high viscosity, hydraulic scroll differential gear is recommended.

Main Application of LLW Horizontal Worm Screen Centrifuge

1. Our industrial filtration centrifuge has successfully applied to oxalic acid, ethylenediamine,paranitroaniline, TCCA, PVC, ammonium phosphate, ammonium sulfate, copper sulfate, fumaric acid, sodium carbonate, sodium sulfate, oxalic acid, mirabilite, citric acid, AH-salt, soda crystal, sodium thiosulfate, refined soda, lactose, vegetable and plastic granule, etc.

2. Normally, the applicable granule diameter is limited from 0.1 to 5mm, and size is ranged from 0.3 to 2mm. The preferred granule shapes fall into thread and crystalline types. In addition, our machine is well-suited for separation of slurries and deposit solids.

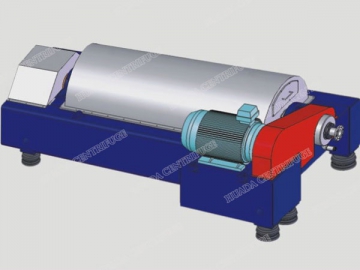

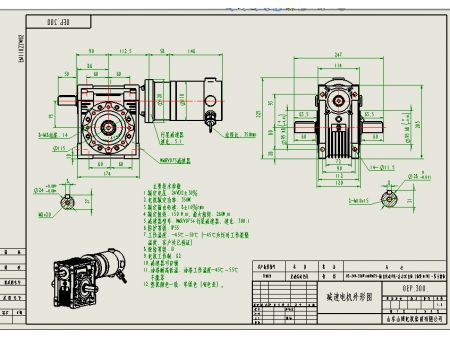

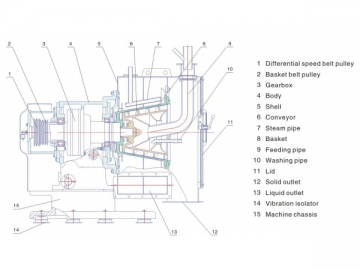

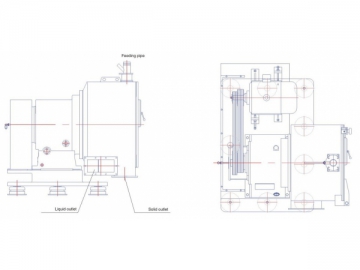

Structure of LLW Horizontal Worm Screen Centrifuge

Outlay of LLW Horizontal Worm Screen Centrifuge

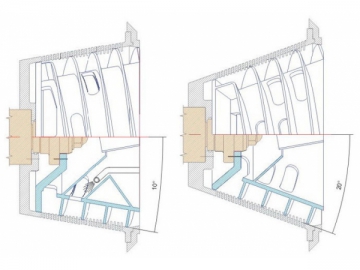

Basket Conical Angle

1. Conical angle: 10°

This angle is highly recommended for cake washing.

2. Conical angle: 20°

This angle is the proven choice for material separation. No large pushing force is required, because solid phase slips from the small end to the large end with the increased centrifugal force.

Technical Parameter of Horizontal Worm Screen Centrifuge (Standard Mode)

| Model | Basket Dia. (mm) | Max. Speed (r/min) | Centrifugal Force | Productivity (m³/h) | Main Motor Power (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| 320 | 2630 | 1240 | 0.5-2.5 | 7.5 | 700 | 1350×1050×1000 | |

| 350 | 3000 | 1770 | 1-3 | 11 | 1000 | 1400×1250×1150 | |

| 450 | 2500 | 1580 | 2-5 | 22 | 1500 | 1600×1400×1300 | |

| 530 | 2000 | 1190 | 3-10 | 30 | 2000 | 1700×1450×1400 | |

| 900 | 870 | 375 | 9-35 | 45 | 3900 | 2340×2390×2030 |

According to different driving mode, our LLW worm screen centrifuge can be fitted with mechanical and hydraulic differential gear. If basket diameter≥530mm, screen scroll centrifuge can be equipped with hydraulic gearbox to achieve enhanced efficiency.

Main Features of Hydraulic Differential Gear

1. Our hydraulic differential gear features inner curve radial piston to offer small size and large output torque which is 2-3 times larger than mechanical gear torque.

2. Feedback control is available to provide overload alarm output terminal, maximal pressure alarm and shutdown function.

3. Differential speed is ranged from 1-30r/min. Fully automatic control and stepless in-line adjustment can be realized without power shutdown.

4. Automatic power compensation function delivers large differential speed compensation range, thus eliminating material jam and offering exceptional adaptability.

5. Differential speed change does not lead to the change of default conveying torque, whereby low differential speed operation is achievable.

6. Cake removal can be performed without rotating basket, thus makes it easy for machine cleaning and troubleshooting.

Technical Parameter of Screen Worm Centrifuge with Hydraulic Differential Gear

| Model | Basket Dia. (mm) | Max. Speed (r/min) | Centrifugal Force | Productivity (m³/h) | Main Motor Power (kW) | Oil Pump Power (kW) | Weight (kg) | Dimension (L×W×H) (mm) |

| LLW530Y | 530 | 2000 | 1190 | 3-10 | 22 | 11-18.5 | 2000 | 1700×1650×1400 |

| LLW630Y | 630 | 1800 | 1140 | 5-15 | 37 | 15-22 | 2500 | 2000×1440×1740 |

| LLW800Y | 800 | 1500 | 1006 | 8-30 | 55 | 37 | 3700 | 2750×1750×2000 |

| LLW1000Y | 1000 | 900 | 150 | 10-50 | 75 | 75 | 6200 | 3200×2155×2280 |

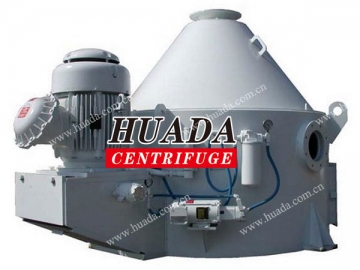

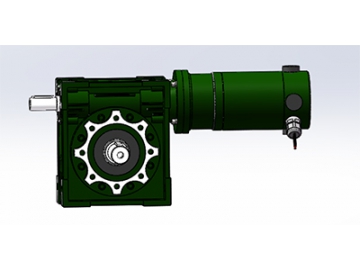

LLW Horizontal Worm Screen Centrifuge with Screw Conveyor

This screw conveyor centrifuge is ruggedly design on the basis of normal LLW horizontal worm screen centrifuge. It is mainly applicable for dewatering materials featuring highconcentration and poor mobility.