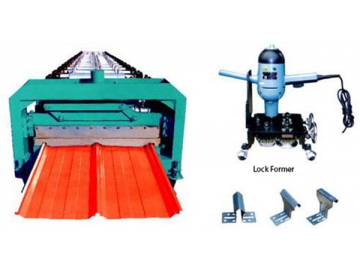

Roof Tile Forming Machine

Application

The roof tile forming machine is commonly used to produce all kinds of elaborately colored concrete tiles.

Features

1. Using a pressing and sieving forming technique, the products have the characteristics of high density, good freeze-residence and water absorption, excellent thermal insulation and heat preservation.

2. Using a mold forming technique, the tiles have the specification of dimensional accuracy, rigorous connection and good waterproofing.

3. With the advanced high-speed running technique, the forming speed is as short as the original one.

4. The whole running course of the roof tile forming machine is controlled by PLC, consistent running cycle, which results in high product stability and low waste.

5. The imported PLC, parts of electric equipment and hydraulic components assure the reliability and stability of the machine.

5. The roof tile forming machine is very versatile. All kinds of exquisite tiles for roofs and walls can be produced by changing the different molds.

7. Good quality exquisite tiles can be produced by mixing into fly ash and waste residue.

8. The high technique, quality and efficiency of the roof tile forming machine assure a high investment return.

| Product dimension | 424x337mm |

| Forming speed | 7-8pcs./min |

| Forming | Press and sieve |

| Production | 3500pcs. (8 hours) |

| Power | 14.45kW |

| Voltage | 380V |

| Mainframe dimension | 3200x1600x2600mm |

Qunfeng is a specialized roof tile forming machine manufacturer based inChina. We also offer block making machine, waste processing equipment, concrete batching plant, concrete curb forming machine, etc.

Customer casesIndex

roof tile making, tile press machine, clay roof tile