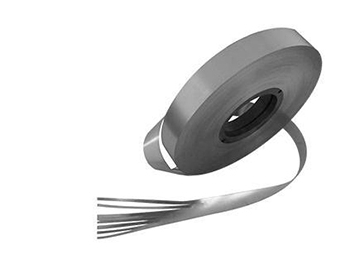

Amorphous Cores

Our amorphous magnetic powder core is made by applying insulating, pressing, and thermal treatments to amorphous powder. Currently, thesoft magnetic materials now used in the electronics industry are FeSi, Sendust, High Flux, MPP, and powder icon cores. Compared with other soft magnetic materials, our amorphous magnetic powder core is inexpensive to produce while still retaining excellent direct current resistance and low power loss. This electronic material is designed to promote the high accuracy, sensitivity, capacity, and miniaturization of the electronic products it’s used in.

Our amorphous magnetic powder core has the following features

1. High saturation magnetic flux density, able to work in high currents without saturation

2. Good magnetic bias and constant inductance characteristics

3. Low-frequency loss

4. Temperature range of -55 to 155 ℃

5. Permeability range is 26, 45, 60, 75, 90, and 125, meeting different requirements

6. The product can be made in ring, E, SDM and other complex shapes

7. Made of Fe, Si and B, it’s affordable for everyday uses

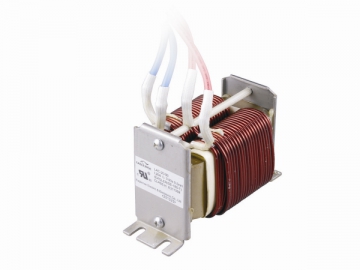

Applications

Because the amorphous alloy is high in saturation magnetic induction and low in loss, it is widely used in electronics, aviation, aerospace, machinery, microelectronics and many other industries. When used in the aerospace industry, it reduces the weight of the power supply and equipment and increases the payload. The electrical and electronic equipment industries use it to keep their power supply systems small, and the amorphous alloy improves their efficiency and prevents jamming. Powder icon core alloys can be used in the power transformer of integrated service digital networks (ISDN)—for example, amorphous ribbons are frequently used in supermarkets and library anti-theft system sensor tags. Its market potential is endless.