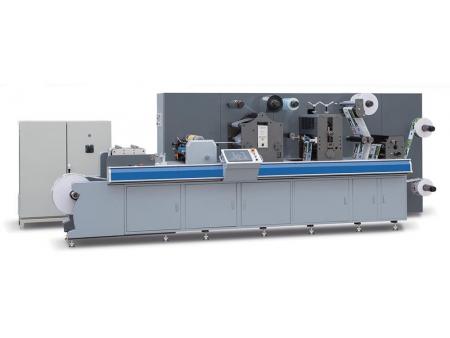

Intelligent Die Cutting Machine

The intelligent die cutting machine is our latest product, presenting itself with a decent and masculine appearance. It features powerful functionality, user friendliness, and high security, bringing customers better experience. This intelligent die cutting equipment saves time, material, labor, and production cost to obtain more benefits.

Structural Features

Main Part

The main part of the intelligent die cutting machine comes in a profile modular frame structure. The front working surface is made of aluminum alloy plates pieced together and treated by special processing technology to ensure surface flatness. There are mounting slots set around the working surface for the installation of different kinds of accessories to meet different production requirements.

The intelligent die cutting machine we offer adopts automatic air expanding shafts each of which is driven by a separate servo motor (Japanese Mitsubishi servo motor). The shafts must be inflated to get the tension for work. When changing materials, the tension should be released before the air is discharged, so as to save a lot of nonproductive time and improve the working efficiency of our intelligent die cutter.

The baffle plate on the air expanding shaft can be easily detached and has the limiting function during working. The shaft tension is subject to the constant tension control realized by high speed internal data calculation. In the case of material blockage or shortage, the machine will stop working automatically.

Operation DeskThe operation desk of our intelligent die cutting machine is fixed on a movable cantilever which can swing or rotate freely during operation. Emergency stop button, power button, start button, and stop button are set at the right side of the operation desk. This way of operation takes the place of the push-pull structure in front of the station, leaving enough space for the installation of other accessories for completing complex processes. The sliding operation desk and station compensation knob allow the users to operate this multifunctional die cutting machine more efficiently.

Safety DeviceLight curtain sensor is installed in the left and right sides of our intelligent die cutting machine. When the die cutter is running, as long as there is an object getting into the protected area, the machine will stop running immediately. If any one of the protective covers is removed, the machine will automatically stop running.

Electrical Cabinet

The electrical cabinet is a separate cabinet mounted at the back of the intelligent die cutting machine. Maintenance channel is available at the back of the die cutter for safe machine maintenance.

All kinds of Mounting Accessories

Main Functions of Intelligent Die Cutting Machine

1. Adjustment of the feeding and discharging shafts along the Y-axis direction

2. CCD function

3. Roll materials splicing

4. Product stacking

5. Mark tracing location die cutting for printing materials

6. Equal interval space die cutting

7. Asynchronous lamination function

8. Producing two products at one time simultaneously

9. Die cutting with reciprocating motion

10. Automatic compensation for color registration

11. Product folding function

12. Innovative safety protection function

HADESHENG is a professional die cutter and cutting die manufacturer in China. Our products come in complete series and we offer the best die cut solutions.