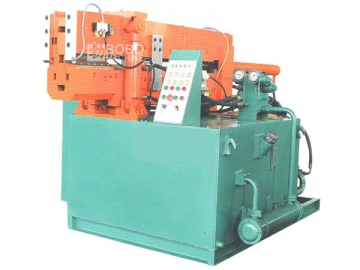

Wheel Butt Welding Machine

The hydraulic wheel butt welding machine welds the wheel in sequence of the roll bending process. The automated processes include clamping, forging, flashing, welding and unloading. The welding transformer holds a capacity in between 400KVA to 1200KVA and covers all standard wheel rim sizes. In comparison with traditional mechanical cam powered machines, the hydraulic wheel butt welder provides more efficient and smooth operating functions. A default centralized lubrication system is implemented to ensure long lasting durability. The wheel butt welding machine ships with a one year parts warrantee.

Technical Specifications

| Rated capacity | 800KVA |

| Primary supply | 380V / 50hz |

| Welding section | 400~4500m² |

| Welding width | 100-500mm |

| Welding thickness | Max. 8mm |

| Adjusting series of primary supply | 8 grade (7-14V) |

| Duty cycle | 50 % |

| Cooling water pressure | ≥0.2Mpa |

| Cooling water temperature | <25 ℃ |

| Cooling water consumption | ≥3000L /h |

| Air pressure | ≥0.4Mpa |

| Clamp open stroke | 20-80mm |

| Max. clamping force | 600KN |

| Forging force | 300KN |

As an experienced wheel butt welding machine manufacturer in China, our company also offers spiral duct machine, Polyurethane Spray Foam Machine, duct elbow machine, punch press machine, and much more.