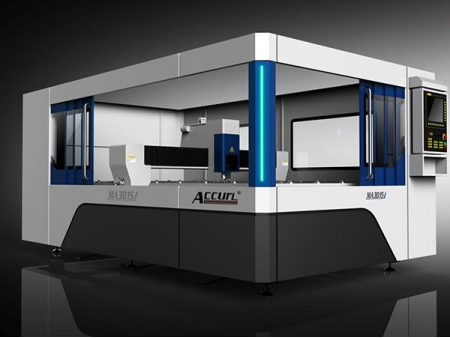

700w CNC Fiber Laser Cutting Machine

Request a Quote

Website: http://accurlcnc.com/5-1-2-700w-cnc-fiber-laser-cutting-machine-for-metal/294489/index.html

for Metal

ACCURL fiber laser cutting machine- big innovation in technology, with exceptional reliability & high beam quality.

Advantages

- With great flexibility, it is easy to cut non-ferrous metals, such as copper and brass. It shows exceptional quality.

- Low production and maintenance costs due to low power consumption. No requirements for resonator gas.

- The fiber laser machine is suitable for marking, finishing and detailing the pieces to be cut.

- Unbeatable high output of fine thickness pieces.

- The machine is easy to install and fast to put into service.

- High cutting speed for the materials with thicknesses less than 4mm.

- With the fiber laser machine, the cutting speed for the material of thicknesses less than 6mm is 5. If using N2 when operating, the speed can be 5 times faster.

- The compact design takes up minimal space, but with no size limitation. The approximate lifecycle is between 4.000 and 5.000 hours.

- The exceptional efficiency of the fiber laser greatly reduced electricity consumption. This machine is 86% more energy efficient than the CO2 laser.

- Lens only need to be changed once a year, within an “optional clean room” environmentally controlled area. The same lens can be used for treating all materials in any thickness.

Characteristics

- High output power

- High quality of laser beam

- Less focus, large focal distance

- Coefficient of efficiency over 30%

- Compact, solid and easy to install

- Low operation cost

- Flexible and durable fiber optic cable

- High electrical efficiency

- Lifespan of the diodes over 100,000 hours

- Low requirements for cooling

Specifications

| Model | ECO-FIBER-1530 /IPG 700W Fiber |

| Transmitting system | Precise ball screw transmitting |

| Laser Power | 700W |

| Working table | 1500*3000 (mm) |

| Max running speed | 40/min |

| X/Y location precision | 0.05mm/m |

| Power Supply | 380v 50Hz |

| X/Y repeated location precision | ±0.05mm |

| Machine gross power | < 10KVA |

| Running temperature | 0°C-40°C |

| Running humidity | < 90% |

| Max. acceleration speed | 1.5G |

| Machine body size | 5080×3350×2000(mm) |

| Applied materials | Thin mild steel, stainless steel and other kinds of metallic sheets; |

| Type | IPG | IPG | IPG | IPG | IPG |

YLS-700W | YLR-1 kW | YLR-2 kW | YLR-3 kW | YLR-4 kW | |

| Output power | 700 W | 1000 W | 2000 W | 3000 W | 4000 W |

| Material | |||||

| Mild steel | 8 mm | 10 mm | 16 mm | 20 mm | 25 mm |

| Stainless steel | 3 mm | 4 mm | 8 mm | 12 mm | 15 mm |

| Aluminum | 2.5 mm | 3 mm | 6 mm | 12 mm | 12 mm |

| Brass | 1.5 mm | 2 mm | 3 mm | 8 mm | 8 mm |

| Copper | 1.5 mm | 2 mm | 3 mm | 8 mm | 8 mm |

| Galvanized steel | 2 mm | 3 mm | 4 mm | 10 mm | 10 mm |

Detailed Pictures