Salt Bath Vulcanization Line

Guoxin's salt bath vulcanization line can completely solve the tough problems existing in traditional vulcanization systems which carry out high pressure steam vulcanization in dangerous high pressure boilers. The temperature in steam vulcanization is adjusted relying on pressure control. To improve vulcanizing speed, the temperature must be increased. Then, the pressure must be raised. This is quite dangerous for a high pressure boiler.

- Pay-off

- Cooling, extruding device

- Main temperature control system, gas circuit, salt feeder

- Pipe temperature control system, salt filter

- Traction device

- Take-up

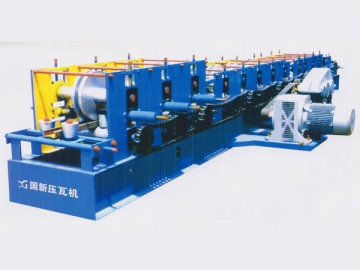

Our salt bath vulcanization line is comprised of a pay-off device, extruder, pipe temperature control system, main machine temperature control system, traction device, take-up device, cooling unit, salt feeder, salt filter, and a gas circuit assembly.

Main Features of Salt Bath Vulcanization Line

1. Safe and Environment Friendly

Our salt bath system for rubber cables works without using steam generated by dangerous high pressure boilers, thus considerably improving safety and at the same time avoiding the pollution of smoke and dust in the air.

2. Energy Efficient

A boiler is unnecessary for this LCM vulcanization line. So, the cost for boiler maintenance and labor is saved. In addition, this rubber machinery employs state-of-the-art salt bath vulcanization technology which ensures electricity saving and high precision temperature control.

In this system, the electricity used to heat the fused salt is about 40-80KW/h and it only costs 1 hour to heat it from normal temperature to 180℃. Plus, power consumption in working is only 7-15KW/h. therefore, the salt bath vulcanization line is quite more energy saving than steam vulcanization line, and meanwhile reduce 10%-30% cost.

3. Fast Vulcanizing Speed

In the salt bath vulcanizing machine, the temperature has nothing to do with the pressure. Depending on the characteristics of rubber vulcanization, vulcanizing speed can be doubled when the temperature rises by 10℃. It can control the vulcanizing speed through temperature adjustment. Our salt bath system only spends a few minutes to let temperatures rise from 174℃ to 203℃. Thus, vulcanization of our salt bath system is faster than steam vulcanization in the pipes with the same length and at the same temperature. Furthermore, the working efficiency is increased by 50%-80%.

4. Capable of manufacturing all kinds of rubbers

It is known that the variety of rubber that steam vulcanization line can make is limited. For example, ethylene propylene rubber (EPR) used for new cables can not come in contact with oxygen in vulcanizing and can only be vulcanized using peroxide. Additionally, silicone rubber vulcanization needs a high temperature that can not be reached by most boilers. Our salt bath vulcanization line, however, can not only work with these materials but also generate no pollution to the environment.

5. Easy Operation

This vulcanization plant employs a unique laser external diameter measuring instrument that can be operated by workers. Therefore, the dependence on professional technicians can be solved.

6. Space Saving

Steam vulcanization line is so slow in vulcanizing that it needs very long pipes. However, the pipeline for vulcanizing in our salt bath vulcanization line is short. Counting the cooling pipe, the total length of our salt bath system is only 60-70m. In addition, the height of the production line does not exceed 2m. So it can save floor space.

Technical Parameters of Salt Bath Vulcanization Line

| Model | ||||

| Twin pay-off stand | 400-630 | 800-1000 | 1000-1600 | 1600-2000 |

| Screw diameter ratio | 16:1 | |||

| Motor power (Kw) | 15 | 37 | 55-70 | 70-90 |

| Salt bath length (m)×Pipe diameter (m) | 48×89 | 48×89 | 48×133 | 48×159 |

| Traction wheel diameter (double wheel) | 600×600 | 800×800 | 1000×1000 | 1200×1200 |

| Take-up | 400/630 | 800/1200 | 1000/1600 | 2000/2500 |

| Maximum finished products OD | 3.0-12 | 7.0-28 | 7.5-50 | 20-80 |

| Line speed (m/min) | 20-70 | 15-50 | 10-40 | 5-35 |