Hand-Formed Noodle Machines

When you encounter recipes for hand-formed noodle, they frequently call for an intimidating array of noodle processing equipment, including noodle roller, noodle steamer, noodle dryer and other complementary noodle machines for making various noodle shapes. With over 50 years of experience in the design and manufacture of noodle making machines, Dongfang Noodle offers one-stop solution of hand-formed noodle machine for commercial noodle plants and pasta production factories that require high-efficiency equipment for hand-shaped noodle production.

Dongfang Noodle has nearly 5 decades of experience in noodle manufacturing equipment. In addition to instant noodle production lines, we also provide hand formed non-fried noodle production lines. Noodles produced by this noodle line are dried by hot air, which are non-fried noodles. Due to hand forming, various shapes of noodle blocks can be made, such as square, round, oval, nest. The hand-formed noodle production line supplied by our company covers a small workshop area, and all parts in contact with food are made of stainless steel, which satisfies high food hygiene requirements.

-

Continuous Noodle-Sheet Press Roller

Continuous roller is the key part of noodle prodcution line. The roller bearing can be quickly removed, and each roller adopts an independent motor, which effectively guarantees the reliability of the transmission, and the structure is simplified, easy to maintenance.

-

High Pressure Steamer

The noodles are sent to the pressure steamer in advance, and the steaming time is about 2-3 minutes, so that the steamed noodles are softer. After thorough sterilization, the noodles feature longer shelf life.

-

Conveyor for Hand-Formed Non-Fried Noodle

Due to the special shape of the hand-forming noodles, it is difficult to realize automatic production. At present, the noodles are manually formed on the workbench in the corresponding shape of the noodle block and put into a plastic box. Usually, the shape of the hand-forming noodles has the nest shape, the folded shape and so on.

-

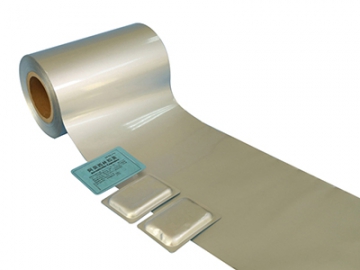

Single Layer Noodle Drying Machine

Workers manually put the formed noodles in a plastic noodle box, and then put the noodle box into the dryer to dry. Usually it is the single-layer flat dryer, using hot air to dry, and the mesh belt is made of stainless steel 304, drying time is about 40 minutes. The capacity is from 250 kg to 1200 kg per hour. This process ensures that the nutrient composition of the noodles are not lost, and the final product has the bright color and the strong chewiness, which are also the features of hand-forming noodles.