8-Shaped Rebar Molding Machine

SKZ 8-shaped rebar molding machine (Mode: KZHD16B)

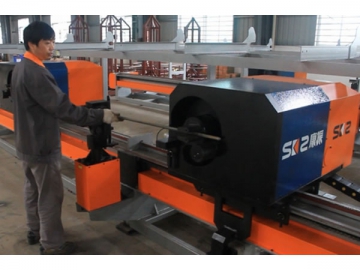

Product IntroductionAn 8-shaped rebar molding machine is a vital component to any lattice girder, though its complex structure often leads to difficulty processing and a large number of operators. To solve that problem, with dedicated research and development of CNC rebar bending machines, have improved upon and upgraded the traditional structure and functions of rebar processing equipment in accordance with the special shape and requirements of the 8-shaped rebar. The newly developed machine makes formerly complex processing and turns it into an easy, standard, highly efficient and energy saving process. To ensure the final product quality, our technicians will go to the processing site and lean of difficulties and problems that occur with traditional bar molding devices, and will then work with our research and development teams to overcome those issues. That is why we have utilized advanced concepts and modernized manufacturing techniques (also known as lean manufacturing) in our designs, saving space and labor. The 8-shaped rebar molding machine is part of a concrete and ordered production line, effectively improving work efficiency.

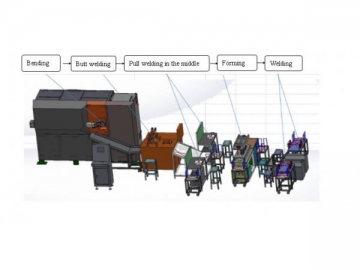

Production Process of Our Bar Molding Device

| Process | Workstation | Worker | Equipment | Technical requirement | Time |

| Bending and forming | 1 | Operator | 8-shaped rebar bending machine | Bent into an 8-shape | 15s |

| Butt welding | 8-shpaed rebar butt welding machine | Smooth welded joint, no dislocation | 4s | ||

| 8-shaped rebar pull welding in the middle (Some projects don't have such requirement) | 2 | Welder | CO2 protective welding machine | Fully welded, specified welding length | 15s |

| Butterfly-shaped rebar forming | 2 | Operator | butterfly-shaped hydraulic rebar molding machine | Specified shape and size | 8s |

| Butterfly-shaped rebar welding | 2 | Welder | Electric welding machine | Fully welded on both sides, four corners are allowed within tolerance range. | 30s |

Notes: According to the production process of this equipment, a pair of butterfly-shaped rebars can be produced in every 30 seconds Parameters

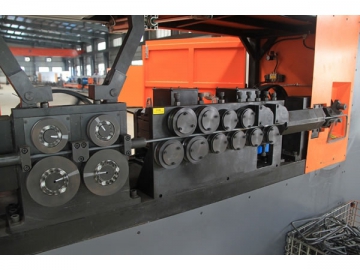

Parameters| CNC 8-shaped rebar molding machine | 8-shaped rebar butt welding machine | Butterfly-shaped hydraulic rebar forming machine | |||

| Model | KZB16 | Model | KZDH125 | Model | KZDX100 |

| Bending rebar diameter | Φ14 Φ16 | Butt welding rebar diameter | Φ14 Φ16 | Cylinder size | Φ100Χ200mm |

| Max feeding speed | 6 0m/min | Production efficiency | 3 00units/hour | Nominal force | 100KN |

| Production efficiency | 2 0 0 units/hour | Rated power | 125KVA | Max stroke | 200mm |

| Rated power | 25KW | Max upsetting force | 40KN | Max opening size | 280mm |

| Working temperature | -5℃- 40℃ | Max feeding stroke | 40-50mm | Cylinder descending speed | 60mm/s |

| Cylinder pressure | ≤0.6MPa | Cooling water consumption | 3 00L/H | Cylinder ascending speed | 60mm/s |

| Size | 3150*1200*2000mm | Size | 1770*1655*1230mm | Height | 860mm |

| Size of working surface | 590Χ300mm | ||||

| Cylinder volume | 80L | ||||

1. This rebar processing equipment is applicable for the production of 8-shaped rebars in lattice girders.

2. Our rebar molding instrument completes the bending and forming processes in a single operation cycle, with no manual intervention.

3. The automatic feeding and discharging device ensures no manual feeding or material being stacked.

4. Using this bar forming machine makes complex processing easier, standard, highly efficient and saves energy.