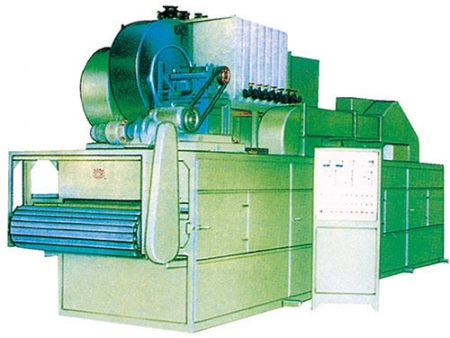

Belt Dryer

Belt dryer is mainly consists of air intake unit, air ventilation unit, air cycle unit, belt, steam pipe, discharge system for condensation, dehumidification system, feed unit, transmission device and control system. It is suitable for bulk-oriented and continuous drying production. The tank in the belt fryer is made up of several standard sections. Length To reduce installation space, multi-layer belt dryer is adopted. Commonly used ones include three-layer type with two drying chambers at each layer and five-layer type with two chambers at each layer.

Working Principle

Feed device is able to bring the material from the hopper and evenly distribute it on the belt, which is made of stainless steel cloth with holes of 12 to 60 meshes. The transmission device enables the belt to move back and forth in the dryer. The blast blower induce air and then the air is heated through electrical heating, steam heating or hot-air heating process. Later, the heated air flow through the moving belt. Through the heat exchange between the hot air and the material on the belt, the materiel is dried, while the hot air is cooled. Part of the air is condensed into vapor which will be expelled from dehumidification holes. A majority of the air is recycled.

Characteristics

1.We can adjust the speed of the belt properly to achieve reasonable residence time of the material and high product quality.

2. Both storage silo, which entails a blender, and distributing device are designed in accordance with specific material characteristics. As a result, lumpy materials can be scattered easily without changing nature of the material. With the unique distributing device, the thickness of the material on the belt is controllable. Furthermore, the distributing device is able to ensure even material distribution in both longitudinal and horizontal directions on the belt.

3.The belt dryer is separated into five sections. In each section, there will be separate compensation inlet for fresh wind, heater, circulating fan, filter in air duct and dehumidification holes.

4. Both heater and circulating fan should be installed at the bottom of the dryer. The dryer is fitted with quick-opening doors at both ends, which facilities cleaning and maintenance. A properly inclined wind deflector is adopted to ensure uniform wind distribution and small temperature difference in the horizontal direction of the belt. In addition, cleaning of the deflector becomes easier as well. Lower belt in the dryer should be slightly inclined to facility material collecting and cleaning as well.

5.The belt makes use of 8-centimeter heat insulated aluminium silicate seal to ensure high sealing efficiency and improve working environment.

| Model | |||||||

| Section Number | 4 | 5 | 4 | 5 | 4 | 5 | |

| Belt Width (m) | 1.2 | 1.6 | 2 | ||||

| Drying Zone Length (m) | 8 | 10 | 8 | 10 | 8 | 10 | |

| Distributing Thickness (mm) | 10-80 | ||||||

| Working Temperature (oC) | 50-120 | ||||||

| Steam Pressure (Mpa) | 0.2-0.6 | ||||||

| Steam Consumption (Kg/h) | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 | |

| Heat Exchange Area m2 | 272 | 340 | 352 | 440 | 448 | 560 | |

| Drying Time ( h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 | |

| Drying Intensity (Kg water /h) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 | |

| Blast Blower Number | 5 | 6 | 5 | 6 | 5 | 6 | |

| Total Power for Blast Blower (kw) | 9.9 | 12.1 | 9.9 | 12.1 | 18.2 | 22.2 | |

| Total Power (kw) | 11.4 | 13.6 | 11.4 | 13.6 | 19.7 | 23.7 | |

| Dimension | Length (m) | 10.05 | 12.05 | 10.05 | 12.05 | 10.05 | 12.05 |

| Width (m) | 1.5 | 1.5 | 1.91 | 1.91 | 2.33 | 2.33 | |

| Height (m) | 3.15 | 3.15 | 3.15 | 3.15 | 3.65 | 3.65 | |

| Weight (Kg) | 4800 | 5780 | 5400 | 6550 | 6350 | 7800 | |