Workover Tools

Application

1. Determines fish depth

2. Finds the shape of the top of the fish

3. To check the deformed shape of the internal diameter of the casing

The Impression blocks are available in flat-bottom type and conical type

| Specification | Thread Connection | I.D. of lead die | Length(mm) | Total length | |

| O.D. | Thread Connection (in) | ||||

| 270 | 203 | 6 5/8REG | 40 | 150 | 450 |

| 225 | 165 | 4 1/2IF | 40 | 130 | 400 |

| 195 | 159 | 4 IF | 30 | 120 | 350 |

| 170 | 121 | 3 1/2IF | 30 | 120 | 300 |

| 120 | 108 | 2 7/8IF | 20 | 100 | 300 |

| 100 | 89 | 2 1/2ZG | 20 | 100 | 250 |

The Cutting pilot mill shoe can be used to mill downhole junk such as drill pipes, drill collars and tubing, etc.

| Type | Outside size (mm) | Connection | Casing Size (in) |

| ф114×ф38×580 | NC31 | 5 1/2 | |

| ф154×ф50×610 | NC38 | 7 |

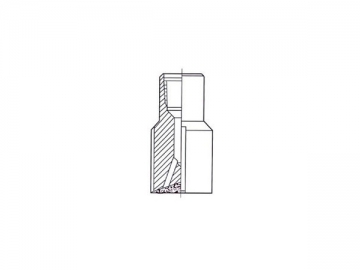

The taper mill tap is a special tool for opening up a passage within the casing.

| Type | outside size(mm) | Connection | Casing Size (in) |

| ф114×1000 | NC31 | 5 1/2 | |

| ф116×1000 | NC31 | 5 1/2 | |

| ф118×1000 | NC31 | 5 1/2 | |

| ф120×1000 | NC31 | 5 1/2 | |

| ф144×1200 | NC38 | 7 | |

| ф154×1200 | NC38 | 7 | |

| ф158×1200 | NC38 | 7 |

The flat-bottom mill shoe is used to mill downhole junk with its bottom face overlaid with YD alloy.

| Type | O.D (mm) | Connection (Box) | Casing Size (mm) |

| 89 | 2 3/8 REG | 95.2-101.6 | |

| 97 | NC26 | 107.9-114.3 | |

| 110 | NC26 | 117.5-127.0 | |

| 121 | NC31 | 130.0-139.7 | |

| 130 | NC38 | 142.9-152.4 | |

| 140 | NC38 | 155.6-165.1 | |

| 156 | NC38 | 168.0-187.3 | |

| 178 | NC50 | 190.5-209.5 | |

| 200 | NC50 | 212.7-241.3 | |

| 232 | NC50 | 244.5-269.5 | |

| 257 | 6 5/8 REG | 273.1-295.3 | |

| 279 | 6 5/8 REG | 298.5-317.5 | |

| 295 | 6 5/8 REG | 320.6-346.1 | |

| 330 | 6 5/8 REG | 349.3-406.4 | |

| 381 | 7 5/8 REG | 406.4-444.5 |

The concave bottom mill shoe is used to grind small objects and other unstable fallen objects within the downhole.

| Type | O.D (mm) | Connection (Box) | Casing Size (mm) |

| 89 | 2 3/8 REG | 95.2-101.6 | |

| 97 | NC26 | 107.9-114.3 | |

| 110 | NC26 | 117.5-127.0 | |

| 121 | NC31 | 130.0-139.7 | |

| 130 | NC38 | 142.9-152.4 | |

| 140 | NC38 | 155.6-165.1 | |

| 156 | NC38 | 168.0-187.3 | |

| 178 | NC50 | 190.5-209.5 | |

| 200 | NC50 | 212.7-241.3 | |

| 232 | NC50 | 244.5-269.5 | |

| 257 | 6 5/8 REG | 273.1-295.3 | |

| 279 | 6 5/8 REG | 298.5-317.5 | |

| 295 | 6 5/8 REG | 320.6-346.1 | |

| 330 | 6 5/8 REG | 349.3-406.4 | |

| 381 | 7 5/8 REG | 406.4-444.5 |

The rolling-ball flat-bottom mill shoe whose bottom face is overlaid with YD alloy is used to fully grind junk stuck within the downhole. Additionally, rolling balls which are installed on the cylinder face of the mill shoe can guarantee the device will not damage the inside wall during milling operation.

| Type | Outside size (mm) | Connection | Casing size (in) |

| ф118×460 | NC31 | 5 1/2 | |

| ф146×480 | NC38 | 6 5/8 | |

| ф155×500 | NC38 | 7 |

The inner tooth shoe is mainly used to mill damaged fish tops, such as tubing and drill pipes.

| Type | Outside size (mm) | Tooth numbers | Connection | Casing size (in) |

| Ф95×430 | 24 | NC26 | 4 1/2 | |

| ф114×500 | 26 | NC31 | 5 1/2 | |

| ф136×500 | 30 | NC38 | 6 5/8 | |

| ф152×500 | 30 | NC38 | 7 |

The outer tooth shoe is a special tool for washing over casing walls and cutting fish tops. Additionally, it is used to mill away cement sheaths, mineral crystals and some edge burrs left from the casing wall.

| Type | Outside size (mm) | Tooth numbers | Connection | Casing size (in) |

| ф106×460 | 14 | NC31(210) | 5 | |

| ф110×460 | 14 | NC31(210) | 5 | |

| ф115×500 | 15 | NC31(210) | 5 1/2 | |

| ф118×460 | 15 | NC31(210) | 5 1/2 | |

| ф121×460 | 16 | NC31(210) | 5 1/2 | |

| ф123×460 | 20 | NC31(210) | 5 1/2 | |

| ф126×460 | 20 | NC31(210) | 5 1/2 | |

| ф140×500 | 26 | NC31(210) | 6 5/8 | |

| ф142×500 | 26 | NC31(210) | 6 5/8 | |

| ф144×500 | 26 | NC31(210) | 6 5/8 | |

| ф146×500 | 26 | NC31(210) | 6 5/8 | |

| ф148×500 | 26 | NC31(210) | 6 5/8 | |

| ф150×500 | 26 | NC31(210) | 6 5/8 | |

| ф152×500 | 28 | NC38(310) | 7 | |

| ф154×500 | 28 | NC38(310) | 7 | |

| ф157×500 | 28 | NC38(310) | 7 | |

| ф159×500 | 28 | NC38(310) | 7 |

The washover shoe is also called an oriented washover mill which is used to remove all kinds of impurities between the pipe strings and casings. The washover shoe is applied to wash cements, hard sand, gypsite and calcium carbonate in annular spaces.

| Type | Outside size (mm) | Tooth numbers | Connection | Casing size (in) |

| ф95×75×1300 | NC26 | For 2 7/8" tubing | 4 1/2 | |

| ф118×95×1300 | NC31 | For 3 1/2"tubing | 5 1/2 |

The pear type mill shoe can be used to mill small local deformations of the casing and finish all flanged edges, burrs of casing at coupling caused by all kinds of tools during running in hole and by perforation as well as remove all minerals and other hard settings around the well wall so as to restore casing drift diameter.

| Type | Outside size(mm) | Connection | Casing Size (in) |

| 90 ~ 96 | 2 3/8 REG | 4 1/2 | |

| 96 ~ 102 | NC26(2A10) | 4 1/2 | |

| 104 ~ 112 | NC26(2A10) | 5 | |

| 112 ~ 124 | NC31(310) | 5 1/2 | |

| 142 ~ 152 | NC38(310) | 6 5/8 | |

| 152 ~ 164 | NC38(310) | 7 |

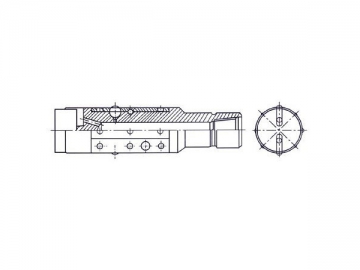

The pilot wedged mill tap is a special tool for opening up a passage within the casing.

Specifications| Type | Outside size(mm) | Connection | Casing Size (in) |

| ф110×ф50×1500 | NC26(2A10) | 5 1/2 | |

| ф118×ф50×1500 | NC31(210) | 5 1/2 | |

| ф140×ф80×1500 | NC38(210) | 7 | |

| ф155×ф80×1500 | NC38(210) | 7 |

The breaking and milling tool is a tool used to cut and mill a sections of the casing so drilling can continue more smoothly.

Specifications| Type | Outside size(mm) | Connection | Casing Size (in) |

| 118 | NC31 | 5 1/2 | |

| 152 | NC38 | 7 | |

| 220 | NC50 | 9 5/8 |

The compound washover head is used to renovate catch OD and remove residues such as rock, sand, and solid cement around fish, etc. The wash over heads are available in composite type washover heads and arched type washover heads The composited type washover head is mainly used for removing casings during workover operation.

| Specifications and parameters for compound washover head | ||

| Type | Connection | Max. Catch OD |

| 7"FWJP | 153 | |

| 8 5/8"FWJP | 190 | |

| 9 5/8"FWJP | 212 | |

| 9 5/8"FWJP | 215 | |

| Specifications and parameters for composite type wash-over head | ||

| Type | Connection | Max. Catch OD |

| 7"FWJP | 153 | |

| 8 5/8"FWJP | 190 | |

| 9 5/8"FWJP | 212 | |

| 9 5/8"FWJP | 215 | |

The milled tap pup joint is a tool used for opening up passages in the casing.

Specifications| Type | Outside size(mm) | Connection | Casing Size (in) |

| ф120×1000 | NC31 | 5 1/2 | |

| ф120×1200 | NC31 | 5 1/2 | |

| ф120×1500 | NC31 | 5 1/2 | |

| | ф160×1200 | NC38 | 7 |

| ф160×1500 | NC38 | 7 |

.jpg)